WhatsApp)

WhatsApp)

ME Long Teng Grinding Media in Kalumbila has stepped up production of mill balls to meet rising demand from mining companies in Zambia and neighbouring countries. A joint venture between Longteng Grinding Media of China and Elecmetal of Chile, the multimillion dollar plant in Kalumbila will see mining companies sourcing mill balls locally than ...

Union Process is the source for the most uptodate information on grinding balls and other media. Click the link above to view a detailed sheet, outlining factors to consider when selecting grinding media, along with specifications on the most common types of media.

Grinding Ball Production Nylonwheels Ingrinding ball production Process Parameters Optimization of Silica Sand Nanoparticles Ball milling is a method for fine powder grinding and fabrication of relationship between grinding ball hardness and ore hardness Grinding ball is a large consumption of materials in grinding production ...

In ball milling, materials consumption by wear represents a very high production cost, and must be minimized by the proper selection of materials, especially those for balls.

"Heat treatment equipment, oil quenching and tempering production is widely used for high chrome grinding media balls or steel balls heat treatment to enhance the balls hardness." "By nature of the repetitive heating and cooling cycles, conveying baskets deteriorate over time and as a result require replacement and maintenance.

calculate a separate cost of production for grinding balls produced from grinding bars produced by Longteng. The nature of the information provided by Longte during Inv 316 : During Inv 316, Longte provided three sets of data relevant to the question asked in part (a): 1. The cost of production for grinding balls produced by Longte where Longte is

By hammer forged, the balls have good density and strengths in favor of impact grinding. And rigidly managed forging process ensuring spherical ball shape. ALLSTAR Group is the leading company in the production marketing of grinding media in China

The manufacturing process of casting chrome grinding media consists of 6 Main Steps: Melting – Raw material analysis – Molding(making balls) – Seprating Cleaning – Heat Treatment – Packaging. For each step matches with the certain equipment, including induction melting furnace, balls making production line (metal mold), grinding media separating and cleaning machine, heat treatment ...

Method of balls rolling on ball rolling mills is one of the most modern production methods. Transversal rolling of balls from the round billet is economical. It differs from other methods due to the possibility to produce grinding balls on the uninterrupted automated aggregates, which allows 2 to 8 times to increase the output and 1015% to ...

Keywords : quenching, grinding balls, wear rate Introduction In Zimbabwe grinding balls are produced from scrap metal and are used as grinding media in gold processing. For the production of grinding balls, incoming scrap metal is segregated according to .

Ball Star Industries is a wellknown top player in the production of Precision Balls having a stateoftheart manufacturing facility housing the most advanced machinery and equipment to produce Balls with the widest range of Sizes and Grades in the following materials:. Carbon Steel (AISI 1010, AISI 1085) Chrome Steel (SAE 52100) Stainless Steel (AISI 300 Series AISI 400 Series)

Jun 23, 2020· The region that dominates the global Forged Steel Grinding Balls market is the Asia Pacific, contributing to almost half of the consumption and production of Forged Steel Grinding Balls. Key regions that contribute to this immense growth include Thailand, Vietnam, India, and South Korea. The regions that have been considered in the study are:

The company L N was founded in 1997 by WolfMichael Litzkuhn and Guido Niederwipper in Lindlar. Since the first produced grinding ball the production line has been constantly improved and modernized. Today, we achieve an annual capacity of tons grinding balls .

Ball Mill Grinding Plants Ammermann Pty Ltd. The two rollers rotating in opposite directions exert very high pressure on the material effectively crushing and weakening the particles microscopic cracks so that the subsequent fine grinding is easier when used as a pregrinding system in ball mill circuits production increases of up to 100 and more can be achieved

Grinding Balls Production Lines. Production line for producing cast grinding balls grinding balls production lines XSD Sand Washer. The efficient sand washing machine of XSD series is a kind of cleaning equipment of international advanced level for sand and slag pellets, developed on the basis of

Factors affecting grinding efficiency of ball mill cement . Ball mill is a kind of crushing equipment which is widely used in the field of industrial production The upsizing of ball mills is one of the research focuses at home and abroad This paper shares the factors that affect the grinding efficiency of ball mill 1 Grinding feeding properties

The production process of casting grinding balls: The casting grinding ball is a kind of grinding balls which uses the medium frequency electric furnace to melt the scrap steel, scrap iron and so on. The furnace charge is fully melted and the precious metal alloy (such as ferrochromium, Ferromanganese, ferrovanadium, etc.) is added to the ...

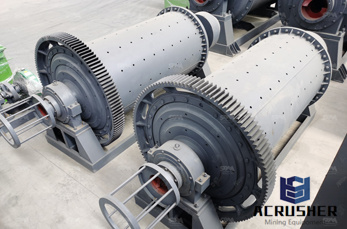

Automatic Casting Grinding Balls Production Line adopts the sand coated metal mold type process technology, widely used to produce the chrome ball grinding media (mill ball), crankshaft, brake drum, wheel hub, casting ball, casting section, water meter case, engine cylinder cover and some other mediumsmall size of castings.

Ningguo Zhicheng does not only offer excellent grinding ball making machines,but also production technology in producing cast grinding we mainly introduce the grinding balls from our customers who are using our grinding ball machines to produce grinding steel balls. PRODUCTS: 1. High,Middle And Low Grinding Steel Balls 2. Specification

Dec 21, 2016· Basically, a ball poured of cast iron. This type of production of grinding balls is expensive also. In addition to energy consumption, a large percentage of "waste" in production affect to the cost of the finished product. Today, the most competitive technology of production the steel grinding balls is a helical rolling of round billet.

of the hardness of the grinding balls. Cast Balls Production line . 1. We use high quality alloy iron and carbon steel scrap iron as raw material,and a medium frequency electric furnace for smelting. The chemical composition and optimal proportions are created by our technicians through continuously testing. 2. The hardness and toughness of the ...

In 2009, our company developed the first HX80130 semiautomatic grinding ball casting production line to solve the technical problems such as heavy labor intensity, bad working environment, low production efficiency and unstable quality of large diameter ballcasting. The line adopts metal mould, sodium silicate clay sand and artificial fixed ...

Jun 10, 2020· Grinding Ball, ALLSTAR INDUSTRY GROUP LIMITED, a certified ISO 9001 company, is the worldleading manufacturer of grinding media ball, grinding steel ball, forged steel ball, casting steel ball with annual production capacity of 100,000 metric tons.

Tube mills are usually fed balls smaller than 2 in., whereas 4 or 5in. balls are more commonly used for ballmill grinding. A much higher grinding capacity is obtained in tube mills by using steel media instead of pebbles, but in making such a conversion serious consideration must be given to the ability of the steel shell to withstand the ...

WhatsApp)

WhatsApp)