WhatsApp)

WhatsApp)

Concrete dust odor hazard source tracking remedy: this article describes odor dust complaints traced to concrete: new pours, sawing or cutting concrete, substances spilled onto and absorbed into concrete, and other concrete or masonryrelated odor and dust hazards. We include citations of expert sources on concrete dust exposure hazards, and we discuss how to deal with odors from wet or ...

Cement and concrete manufacture Where are the hazards? High levels of dust can be produced when cement is handled, for example when emptying or disposing of bags. Scabbling or concrete cutting can also produce high levels of dust that may contain silica. What are the risks?

(2011), it was observed that particles released from cement factory. In another study on agricultural plants, it was found that the particles released from cement factory caused air pollution in plants (Bilen, 2010). The factories must implement the control methods developed in order to minimize the negative effects .

Frequently Asked Questions . ... Other ways to reduce or eliminate exposures include using different materials, such as aluminum oxide instead of sand for abrasive blasting, or using work practices that help minimize dust. The "CreateAPlan" tool on this website provides examples by material and task for controlling dust.

South African cement group Pretoria Portland Cement (PPC) is to undertake a major project to reduce dust emissions at its De Hoek factory in the Western Cape. The cost of the project is about R70 ...

Where CKD stands for Cement Kiln Dust. Because masonry cement requires additional lime, the IPCC Guidelines provide an equation, based on masonry cement production parameters, to estimate CO2 emissions resulting from the additional lime. The equation, and its components, is presented in Box 1.

Jan 14, 2016· In other cement industry innovations to reduce carbon emissions, the technology focuses on creating less carbon intensive cement. Calera takes captured CO2, mostly from utility plants, and combines it with an alkalinity solution and calcium in the form of carbide residue to convert the CO2 to calcium carbonate and water.

Evalua tion of cement impact to ... exposure on the health status of portland cement factory ... Alternative methods and equipment to manufacture cement, are summarized and ways to get rid off or ...

Abstract. In this study, environmental impact on air quality was evaluated for a typical Cement Industry in Nigeria. The air pollutants in the atmosphere around the cement plant and neighbouring settlements were determined using appropriate sampling techniques.

Cement CO2 Emissions. Cement CO2 Emissions: Cement manufacture causes environmental impacts at all stages of the process. These include emissions of airborne pollution in the form of dust, greenhouse gases, noise and vibration when operating machinery and during blasting in quarries, and damage to countryside from quarrying.

Portland cement concrete (ACPA, 2002). It is therefore important to conduct an Environmental Impact Assessment of a proposed cement factory considering the negative impacts of cement companies on the environment. This study will also develop a predictive model .

When laying concrete block, have different sizes on hand to avoid cutting or hammering to make them fit. Work in ways that minimize the amount of cement dust released. Where possible, wetcut rather than drycut masonry products. Mix dry cement in wellventilated areas.

the cement industry corresponds to the dusts. Indeed, the dusts can be emitted at every stage of the manufacturing process of the cement: extraction of the raw material, crushing, production, etc. The main objective of this research is to assess the impact of the dusts given out by a cement factory .

The general health problems that may arise from prolonged exposure to cement dust were investigated using black rats (Rattus rattus L.) living around a Portland Cement Company in Sagamu, Ogun State, Nigeria. 24 black rats, comprising of 12 rats from the cement factory and 12 rats from an environment free from cement dust were used for the study.. Elemental analysis, hematology examination ...

AIR POLLUTION CONTROL TECHNIQUES FOR THE CEMENT MANUFACTURING INDUSTRY: A CASE STUDY FOR ZIMBABWE D. Zimwara1, L. Mugwagwa1, ... Figure 1 shows part of a cement making factory in Zimbabwe. Figure 1: Cement Production Plant (Cement Company, Zimbabwe) ... 3 ENVIRONMENTAL IMPACTS OF CEMENT MANUFACTURE

Particulate matter and elemental emissions from a cement kiln. ... Impact of emissions of cement plant on ambient air quality around its vicinity. ... OlatunjiThe Sagamu cement factory, SW Nigeria: is the dust generated a potential health hazard? Environmental Geochemistry and Health, 29 .

This study examines the impacts of cement dust emissions on physicochemical properties of soils within 10km radius from the plant (factory) in Ashaka area, Gombe State. Standard procedures used in soil sampling involves collection of soil samples along a transect aligned in the northeast to southeast direction in order to reflect the

Cement factories clean up act. ... that cement plants can reduce their impact on the environment. She lives with 19 members of her family about three kilometres from a factory that introduced ...

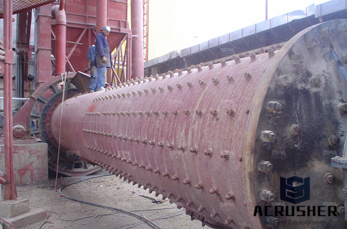

Portland cement and the environment. Portland cement is manufactured by heating limestone or chalk with clay in a rotary kiln to a high temperature (about 1450°C) to produce hard nodules of clinker that are then ground with a little gypsum in a ball mill.

Human Health Risk due to Cement Dust Exposure Key Facts in Brief • Some of the initial studies have shown that the incremental individual risk due to emissions of the cement plant is very low not only with regard to health effects, but also in relation to toxicological and cancer

Chapter 7 Control of Dust Transmission World Health Organization. Section explained how dust could be controlled at emission, transmission or ... applications: for example, placing a lid on a sieve can have a major impact in reducing ... airborne dust, and this also often helps reduce skin and clothing ..... successfully used to treat the dustladen gas from shaft kilns of cement plants.

Similarly to our findings, Merenu et al. 2007 [6] investigated the effect of cement dust exposure on 56 cement factory workers with a mean of 10 years exposure to cement dust on lung function. They found that the vital capacity and forced expiratory volume in one second were significantly lower in cement factory workers than in control subjects.

Industrial activities play a key role in the economic wellbeing of a country but they usually involve processes with a more or less profound environmental impact, including emission of pollutants. Among them, much attention has been given to airborne particulate matter (PM) whose exposure is ubiquitous and linked with several adverse health effects mainly due to its size and chemical composition.

More than 250,000 people work in concrete manufacturing. Over 10 percent of those workers 28,000 experienced a jobrelated injury or illness and 42 died in just one year. Potential hazards for workers in concrete manufacturing: Hazard: Exposure to cement dust can irritate eyes, nose, throat and ...

WhatsApp)

WhatsApp)