WhatsApp)

WhatsApp)

animation of raw mill in cement,Cement making machine,Cement plant . Cement production line: cement making plant is used in cement raw material crushing plant. Line crushing: line is the main raw material for . Rawmill Wikipedia into "rawmix" during the manufacture of cement..then ground to make cement in the cement mill ...

Feb 26, 2013· This film demonstrates all aspects of the FL ATOX® raw mill: how it saves space and energy and why it has been proven to deliver reliable operation for crushing and grinding all types of ...

Jan 22, 2016· Raw mill fan in cement industry carries gas and raw meal. The pressure drop in raw mill fan is very high. If a vertical roller mill is used for raw grinding in cement industry then a large raw mill fan is installed. Usually cement industries use centrifugal fans to carry out this process. Induced Draft Fans. Induced draft fans supply the ...

Portland cement manufacturing plants are part of hydraulic cement manufacturing, which also includes natural, masonry, and pozzolanic cement. The sixdigit Source ... In the wet process, water is added to the raw mill during the grinding of the raw materials in ball or tube mills, thereby producing a pumpable slurry, or slip, of approximately ...

Cement plant locations and information on United States can be found below. For full access to the database, purchase The Global Cement Report™, 13th Edition.

The planned new plant is located nearly 500 km south of Cairo in Sohag. The LOESCHE scope of delivery includes a raw material mill with a capacity of 540 t/h of cement raw meal, a cement mill with an output of 350 t/h of clinker as well as a coal mill with an output of 45 t/h. VIEW MORE

cement manufacturing plant from india we are manufacturer and exporter of: 1. turnkey cement plants 2. grinding unit cement plant in india 3. cement grinding unit 4. cylindrical grinding machine 5. ball mill for cement grinding in meerut, uttar pradesh, india.

animation of raw mill in cement plant; animation of raw mill in cement plant. nebiros character . firestorm than blasts nebiros turning the water in his body to cement, seemingly killing hm. new 52. nebiros was summoned by tobias whale, using the demon chalice which was thought to be just a.

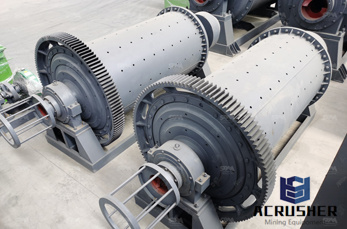

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw .

Feb 10, 2016· VRM vs Ball Mill for Cement Grinding. Good Days! Gentlemen, Anybody in this forum who have had some practical/extensive experience on Vertical Roller Mill being used for cement grinding? We are planning to put up a new cement grinding plant using Vertical Roller Mill(300350 – TPH) and before implementing the project, we would like to

Mar 03, 2015· The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine. It is widely used in building material, chemical industry, etc. There are two ways of grinding: the ...

Sep 11, 2013· LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations. Special ...

Raw Mill Is Widely Used In Cement Plant. Raw mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and .

animation of raw mill in cement plant. Quitter lanimation The raw materials required to manufacture cement are lizenithne and clay Rocks extracted from the quarry are routed to the nearby cement plant on a conveyor belt The minerals from the quarry are routed to the grinding plant where they undergo initial milling before being reduced to a fine powder Read More

Feb 26, 2013· This is the ATOX movie for raw mill grinding in an animated version. Read more about the ATOX mill here:

This is the 3D Auto cad drawing. This is the second department in the Cement Plant. All related unit foundation drawings are made available in the 3DFoundation Erection drawing.

View the interactive animation of the cement production process to learn how cement is made by CEMEX. Product Support. Get a Quote ... they are transported to the plant in dump trucks or by conveyor belt. 3. Crushing ... Raw material mill.

The raw mix burns at 1500 °C producing clinker which, when it leaves the kiln, is rapidly cooled with air fans. So, the raw mix is burnt to produce clinker : the basic material needed to make cement. conveyor Next Raw mix kiln cooling Back preheating clinker storage at the plant Raw mill THE CEMENT MANUFACTURING PROCESS : The ...

Raw MillHoppers Cement Plant 3D, formats DWG, 3d cement design hoppers industrial, ready for 3D animation and other 3D projects

Process control optimization of rotary kiln line, raw mill and coal mill at the Adana cement plant in Turkey 20% decrease in standard deviation, 10% longer refractory life, % energy saving, % production increase

raw mill working animation . animation for how to work raw mill in cement plant, vertical roller mill animation,vertical roller mill in cement industry,, atox raw mill in cement plant stone crusher machine LAFARGE LICHTENBURG CEMENT WORKS raw material for cement, the plant Raw mill 1 GRINDING 2 STORAGE,, The priority at Lafarge is the safety of the men and women who

Aug 30, 2012· Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant. There are also various other raw materials used for cement manufacturing. For example shale, fly ash, mill scale and bauxite. These raw materials are directly brought from other sources because of small requirements.

Mill designs. The most important first step in controlling energy consumption is to be aware of the relative importance of the process areas where most energy is consumed. Figure 2 shows a typical breakdown of electrical energy consumption at a cement plant. The most obvious area for attention is that of grinding, both raw and cement.

1927 First Loesche coal mill delivered for the Klingenberg power station in Berlin. 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill (LM D). 1980 Delivery of first modular coal mill (LM D). 1985 Delivery of first selfinerting coal grinding plant (LM D) for the steel industry (PCI ...

WhatsApp)

WhatsApp)