WhatsApp)

WhatsApp)

required four to six ball mills and the amount of concrete is huge for mill foundation construction. If the foundation design is over conservative, it may lead to higher costs.

Stationary concrete batching plant HZS35. Mobile electric selfloading concrete mixer JZR350 series. Mini mobile batching plant YHZS50. Cement ball mill. by:SMART ...

A ball mill can be installed on top of the concrete base when its compressive strength is up to more than 75%. Before installation, check the quality of the basis to ensure that concrete is not affected by the strength of the defect, the number and position of the reserved hole meets the requirements, and the reserved holes have no water ...

Ball mill is widely used in aerated concrete industry. Steel brother thinks that the reasonable determination of loading capacity has a great influence on the ball mill, and the product quality and product efficiency can be improved. Reasonable load of the grinding body. Buy Now.

Balashikha ball mill wear parts processing concrete sand : A special equipment for the production of construction sand and a manufacturer of sandmaking equipment for 40 years, we can provide you with a variety of models to choose ball mill processing concrete sand Mining Sourcing Guide for Cement Ball Mill China ...

Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of grinding media (steel balls). Grinding clinker requires a lot of energy. How easy a particular clinker is to grind ("grindability") is not always easy to predict, but large clusters of belite due to coarse silica in the feed ...

Ceramic ball mill is mainly composed of cylinder, main bearing, reinforced concrete support, transmission part and so cylinder body is provided with a welding combination integral including a shaft head, a sealing head and a cylinder body. the main drive is realized by the belt drive at the end of the reducer of the main motor.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Certain applications require special buckets. When transporting steel balls, an ordinary concrete bucket just isn''t built heavy enough. That is where the GARBRO Ball Mill bucket comes in. This bucket is specially designed to withstand the extreme use of transporting heavy steel balls. With its thick, steel cone, and heavy duty gate, it is ideal for this application.

Jul 10, 2014· A neat idea and I wish I could have talked to the man who tried it. All I can do is talk to people who know he tried it. After some searching I located two of his drums. You can see how hammered ...

Ball Mill For Cement Ball Mill For Cement Suppliers And. Offers 13950 ball mill for cement products about 43 of these are mine mill 5 are cement making machinery and 1 are grinding equipment a wide variety of ball mill for cement options are available to you such as ball mill raymond mill. More Details Concrete Ball Mold

A ball mill is a rotating The cement is bagged transported for concrete production. a comparative analysis of the recent cement grinding METU Feb 11, 2011 The conventional cement grinding system, the ball mill, has very poor and also the other product characteristics, the concrete laboratory of

Calculation of the power draw of dry multicompartment ball mills May 6, 2004 ... In this paper, a new approach for the calculation of the power draw of cement grinding ball mills is proposed.

Drum Mill / Rod Mill TM 300 XL RETSCH. In a drum mill the sample (usually precrushed material) is placed inside the drum with the grinding media (grinding balls or rods) and subjected to external forces. The Ball Mill and Rod Mill Modules are used for fine grinding of solid matter by impact and friction, in wet or dry condition. Get Price

Cement Concrete Ball Mill For Sale . Cement mill for sale cement mill process cement mill cement concrete ball mill for sale a cement mill is the equipment that used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement most cement is currently ground in ball mills cement clinker is usually ground using a cement ball mill this is essentially a large ...

We have Concrete Milling Machine Ball Mill Prices Ball Pul,Looking for affordable ball milling price 4,647 low price ball milling products from 1,549 trustworthy ball milling suppliers on reach out to suppliers directly and ask for the lowest price, discount, and small shipping fees.

Ball mill for cement concrete Henan Mining Machinery Co ... Ball Mill For Cement cz. Ball Mill For Cement Ball mill,Ball mills,Ball mill machines Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ...

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications. It is designed along sound engineering principles ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary ...

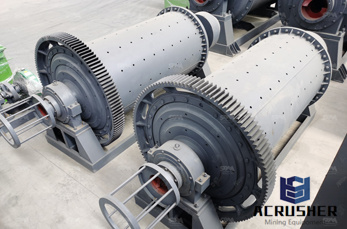

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of ferrous and nonferrous metals. The ball mill can grind ores and other materials either wet or dry.

Ball mills have been the primary piece of machinery in traditional hard rock circuits for 100+ years. They are proven workhorses, with discharge mesh sizes from ~40M to <200M. Use of a ball mill is the best choice when long term, stationary milling can be justified by an operation.

Ball mill is an important equipment to grind the crushed materials which is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc. Further more, ball mill can grind various ores and other materials with dry type and wet type.

Industrial Grinding Mill Equipment For Sale Philippines. Grinder machine for sale in the philippines of concrete floor grinder in the mill,ultrafine mill,raymond mill for sale,straight centrifugal mill,grinding mill fo sale from shanghai is one of the biggest. Live Chat

WhatsApp)

WhatsApp)