WhatsApp)

WhatsApp)

INNOVAT Mineral Process Solutions Vat Leach. Continuous Vat Leaching; combining the efficiency of agitated tank leaching with the simplicity of heap leaching, Continuous Vat Leaching is revolutionizing the mineral processing industry. A no compromise solution to traditional leaching methods. Inquire Now; Extracting Gold By Carbon In Pulp ...

Continuous Vat Leaching; combining the efficiency of agitated tank leaching with the simplicity of heap leaching, Continuous Vat Leaching is revolutionizing the mineral processing industry. A no compromise solution to traditional leaching methods. Engineered to perform in the most demanding environments – extreme heat, high rainfall, lack of water and freezing temperatures are no longer a ...

The present trend in the processing o f minerals is the ... Schematic diagram of equipment setup for the gold leaching process. ... Heap or vat leaching is a process that has been extensively ...

Book. Dec 2005; Mike D Adams ... The ammoniacal thiosulfate leaching process for gold and silver extraction has been reviewed in terms of leaching mechanism, thermodynamics, thiosulfate stability ...

Gold CIL CIP Gold Leaching Process Explained CCDCIL stands for carboninleach. This is a gold extraction process called cyanidation where carbon is added to t

Jul 17, 2020· The Best VAT leaching sett up with minimum installation cost. ... Mineral processing expert 6 views. ... Unity Mining Henty Gold Mine Process Plant Leaching the gold Duration: ...

Pump leaching is a process that grind gold mine with low grade to a certain particles, heap up on the leakageproof bottom mat that concreted by pitch, concrete or plastic cloth, spray the low concentration cyanide solution, alkaline solution, nontoxic solvent, dilute sulphuric acid on the stock heap, make the gold dissolve, the solution with gold heap up, then use active carbon ...

CVL is a mechanical leaching system developed by Innovat Mineral Processing Solutions. The basic concept is to provide, by means of an elevated head tank, intermittent fluidisation of the ore in a swimming poollike vat.

10 Steps For Gold Leaching Using Environmental Gold Dressing Agent. May,24,2019 Flotation Conditioners of Oxidized Zinc and Lead Ore. May,15,2019 The Introduction of Flotation Frothers. May,08,2019 CNFREE Gold Leaching Reagent compared to Cyanide in Gold Mining Plant. April,24,2019

Leaching is a chemical process in mining for extracting valuable minerals from the ore. Leaching also takes place in nature where the rocks are dissolved by water. Post leaching, the rocks areleft with smaller proportion of minerals that they originally contained.

Improving the process performance of gold cyanide leaching . Improving the process performance of gold cyanide leaching reactors 3 literature (Equation [1]) shows that k L a is a function of mixing power intensity (P/V) and superficial gas velocity v s. The coefficients A, B, and C are reactor and applicationspecific. k L a = A

free circulation of the leaching agent. The leaching period is 2 – 4 days and gold recovery lies in the order of 70 – 80%. The cheapest but slowest technique is heap leaching. It is a process usually applied to low grade gold ore. Basically the ore is piled to a given height on an inclined impermeable surface, a so called leach pad.

continious vat leaching small scale defamiliethiels designing of a vat leaching plant for gold processing of Vat Leaching Parameters in Small Scale Mines: Case Study of Tanzania treatment cost at the plant scale [7, 10]. It has been suggested that oxygen injection, instead of air, provides a high oxygen concentration in the slurry and can ...

After the leaching process is complete, the soluble gold must be concentrated and separated from the process slurry. The method of recovery of gold from the process slurry is by carbon adsorption. Adsorption is a term used to describe the attraction of a mineral .

Leaching Equipment, Leaching Tank, Gold Leaching Xinhai22행 With dual impellers rotating and agitating, ore pulps move downward and then diffuse along da

Vat leaching is carried out in vats ranging in capacity from 30 to 1200 tons. Sand for leaching is separated from slime in cones, V boxes, classifiers, and in collecting vats filled by distributors—the overflow in each case being slime or finer portion of the ore. As a rule, leaching is a simple process, involving a vat of wellmixed neutralized sand, ample contact with strong and weak ...

Gold Vat Leaching Mineral Processing Metallurgy. Metallurgical ContentLeaching Gold in VatGold Lixiviation in VatPreparing the Ore for Vat CyanidationReprecipitation of Gold Silver in the Leaching VatsVat SumpsVat Tailings Disposal Gold Leaching done in .

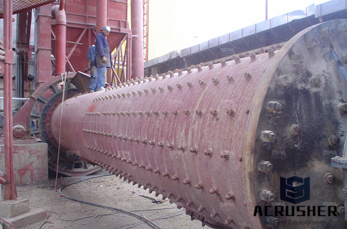

Gold Leaching done in round vats, constructed of wood, concrete, or iron and steel. If wood is used it is covered by a coating of paraffin paint, or by a mixture of asphaltum and coaltar. Concrete and brick vats are not now advocated owing to their great cost and less convenient working, and wooden vats suffer more than iron and steel ones from exposure and from being alternately emptied and ...

In most cases, gold processing with cyanide leaching, usually with carbon adsorption, is still the core technology and the critical thing is understanding the mineralogy in order to optimise flowsheet selection and cost drivers, and get the best out of the process. Metallurgy: the science of .

Gold Ore Processing: Project Development and Operations, Second Edition, brings together all the technical aspects relevant to modern gold ore processing, offering a practical perspective that is vital to the successful and responsible development, operation, and closure of any gold ore processing completely updated edition features coverage of established, newly implemented ...

Day 51, Procedures to obtain gold: Vat Leaching Process ... I have liked this page a lot, but what i suggest is that, more investigation and lab test have to be done for vat leaching to process even sulphide ore,becaus most area especially in Africa (Tanzania) now days vat leaching is the most way of gold processing,and if there is a new technology for vat leaching to leach sulphide may u send me.

SGS MINERALS SERVICES – T3 SGS 869 102008 THIOSULPHATE LEACHING – AN ALTERNATIVE TO CYANIDATION IN GOLD PROCESSING ALTERNATIVES TO CYANIDE IN GOLD PROCESSING THIOSULPHATE LEACHING Thiosulphate leaching is a process that removes gold from gold bearing ores without the use of cyanide. Although not as aggressive a leaching agent as cyanide, ...

Day 51 Procedures to obtain gold Vat Leaching Proc. I have liked this page a lot but what i suggest is that more investigation and lab test have to be done for vat leaching to process even sulphide orebecaus most area especially in Africa Tanzania now days vat leaching is the most way of gold processingand if there is a new technology for vat leaching to leach sulphide may u send me

Heap leaching is an industrial mining process used to extract precious metals, copper, uranium, and other compounds from ore using a series of chemical reactions that absorb specific minerals and reseparate them after their division from other earth materials. Similar to in situ mining, heap leach mining differs in that it places ore on a liner, then adds the chemicals via drip systems to the ...

WhatsApp)

WhatsApp)