WhatsApp)

WhatsApp)

Accumulations of debris or coal anywhere in the pulverizer will increase the chance of a mill fire. The pyrite removal chute should be inspected often to ensure rejected material is removed from the under bowl area. Stoppage of pyrite chute flow can cause debris andor coal .

Oct 25, 2008· Scope of Work Bidder''s scope starts from outlet of mills upto mill rejects storage silo including pyrite hoppers, denseveyors / air lock vessels, dome valves, piping, valves, fittings, transport air compressor, air receiver, storage bunker, and associated .

Coal mill in power plant pyrite laserenatabe. Iron Minerals in Coal, Weathered Coal and Iron in coal is mainly associated with sulphur in the minerals pyrite and jarosite, whilst other iron Ash samples, obtained from the Lethabo electricity power plant, and ground in an alumina ball mill .

coal fired power plant mill operation cost indonesia. the US4 billion coalfired power plant. The IIGF guarantee provides a tenor of 16 years for equity and 21 years for debt, much longer tenors than are typically provided The Central Java Coal Power Plant is a 2,000 MW ultrasuper critical power plant in Batang, Central Java.

Power Plants to use OnLine and other Coal Quality information. 0 10 20 30 40 50 60 ... Ohio Style Texas Style Kansas Style. Slag Related to: Coal Quality – Getting Worse? Plant Equipment – Boiler/Mills Fixed Combustion Process This we can control: Superior Mill Performance Maintain Mills to Preserve ... Need 75% for high pyrite low NOx ...

Jun 26, 2013· coal mill in power plant pyrite YouTube. Jun 26, 2014 ... Coal powder mill applied at coal fired power plant and thermal coal ... mill pyrites removal coal processing plant,Coal Mill In Power Plant... Read more. Mill Reject (Pyrites) Systems United Conveyor Corporation.

pulverizer modification for pyrite separation at the power plant. ... pulverizer modification for pyrite separation at the power plant. award information. ... the unit is designed for separation of pyrites and other minerals from the internal circulating load of the roller mill when preparing minus 200 mesh coal for direct firing. the unit will ...

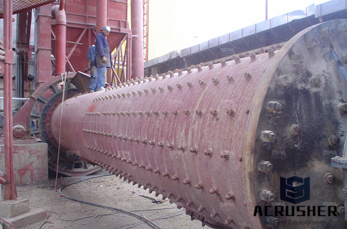

Beater wheel mills are designed to prepare a coal powder airfuel mixture for combustion in furnace chambers of coalfreed power plants by coal drying, pulverizing, classifying and transport. Their multipurpose function usually results in operation instability accompanied by unacceptable vibration.

Dry Separation of Pyrite from Coal. cannot be completed until the coal is finely pulverized. Be cause of dust .... mill. /. /. Pyrite, ball mill. ... 2 Flue gases up to 1,450 °C arise from pulverized fuel combustion in the steam ... power plants (e. g. coal mill), mainly for MHPSE ..... E Grinding ball filling ... MHPSE supplies DGS® mills ...

Working of pyrite hopper in mill in thermal plant. Products. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including, Working of pyrite hopper in mill in thermal plant., quarry, aggregate, and different kinds of minerals.

Aug 25, 2014· Rod Truce of Hansom Environmental Products discusses some of the benefits of removing pyrite and silica from coal during the milling process. Mr. Truce was a presenter at the Power Plant Pollutant ...

Nov 17, 2012· coal mill/pulverizer in thermal power plants shivaji choudhury 2. Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form. Pulverized coal achieved its first commercial success in .

Pyrite chute for coal mill COAL MILL PULVERIZER in THERMAL POWER PLANTS, Pyrite chute for coal mill,9 Nov 2012, Coal pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy, clearance ?Spring pressure for rolls ? Pyrite scraper clearance ? Pyrite rejects chute and/or damper Coal Cleaning In a MagMill EXPORTech Company, .

coal mill roller removal . . than tramp iron chutes for removal of very small amounts of pyrites,, Feed Pipes / chutes Raw Coal Feed Pipes Babcock Ball Tube Mills, Get Price And Support Online; Pyrite Uses In Coal Mills Mill Pyrite Removal System coal mill in power plant pyrite .

The MRS® (Magaldi Mill Rejects System) is a new process concept designed to mechanically handle rejects from coal mills, in a dry way. Rejects are a mixture of different materials (pyrites, stones, tramp iron, etc.) with pulverized coal, requiring a reliable and safe removal system.

In coalfired power plants coal mills are used to pulverize and dry to coal before it is blown into the power plant furnace. The coal is feed into the coal mill through a central inlet pipe where gravity is used to lead the coal to the bottom of the mill, where the grinding table and some heavy rollers pulverizes the coal to particles.

pyrite for ball mill spitsid. coal mill in power plant pyrite grinding mill equipment. pyrite for ball millcoal mill in power plant pyrite stone crusher for sale26 Jun 2014 It was recommended that pyrite impact mill gyptech Pyrite With Impact Crusher hotelbluepearl. pyrite with impact crusher grinding mill chinairon pyrite ore crusher and ...

Mill Rejects. At most coalfired installations, mill rejects ("pyrites") are collected independently from the combustion residuals, but are often combined with the bottom ash in the sluice ...

Coal pulverizer/mill system One of the critical power plant components ... to grind and burn pyrites Pyrite Scraper and Guard Assembly rock. Loesche Mills for solid fuels LOESCHE 1953 500th coal mill plant sold worldwide. 1961 Introduction of hydraulic spring assembly system. 1965 Construction of first pressure mill.

At Melco India, we have expertise in efficient handling of mill rejects generated by coal mills in an ecofriendly manner. We are the pioneers in deploying Dense Phase Pneumatic Conveying concept for handling difficult materials like rejects (sizes upto 40 mm) from Coal Pulverizing Mills to bunkers in power plants.

Coal Mills in thermal power plant Free download as Powerpoint Presentation (.ppt), PDF File (.pdf), Text File (.txt) or view presentation slides online. for thermal powerplant familiarization

THE SOLUTION. Following the approach to adopt the best available technologies for the new Torrevaldaliga Nord power plant, Enel selected Magaldi Power for the design, supply and erection of 3 MRS ® systems to mechanically handle, in a dry way, the rejects from the coal mills. At Torrevaldaliga Nord TPP each Unit is equipped with 6 coal mills (bowl type).

The resulting product, called powdered coal or pulverized coal, is then generally used in a fossil fuel power plant for electricity generation. Pulverised coal is a significant dust explosion hazard, as large quantities are suspended in air for transfer from the mill to the power plant.

Posts about pyrite hopper written by shivajichoudhury. Intent of Specification This specification is intended to cover the following activities and services in respect of all the equipments of Mill Reject System for 2×500 MW units.

WhatsApp)

WhatsApp)