WhatsApp)

WhatsApp)

Technical and Commercial Benefits of Gearless Mill Drives for ... numerous GMDs for ball mills and SAG mills have been installed in the minerals industry. .... Operating Principle of Cycloconverters and its Implications. Two different modes ..... Inching is used to position the mill .

working principle of cement ball mill [PDF Document] ... The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media.

Cement Ball Mill Operating Principle Pdf hangon. cement ball mill operating principle pdf, process crusher Working Principle Our ball mill can grind ore or other materials that can be grinded either by wet process, Get Price And Support Online "EXPERIENCE WITH SYNCHRONOUS AND Cimentec

Operating Principle Of Ball Mill In Japa ... Ball mill is the key equipment for grinding after the crushing process, which is widely used in the manufacture industries, such as cement, silicate, new building material, refractory material, fertilizer, ferrous metal, nonferrous metal and glass ceramics and can be used for the dry and wet grinding ...

Oct 12, 2017· Today we will learn about difference between sag mill vs ball mill. A mill is a machine by which solid or hard materials are broken into smaller pieces by means of grinding, crushing or cutting. This commutation is an essential part of many processes. Various kinds of mills are there with which different material processing takes place.

The basic principle is to measure the ... Ball mills are usually the largest consumers of energy within a mineral concentrator. Comminution is responsible for 50% of the ... about the mill operation is vital. An innovative tool which can deliver information about inmill dynamics has been developed by Magotteaux. It can provide online and ...

Several types of ball mill exist. They differ to an extent in their operating principle. They also differ in their maximum capacity of the milling vessel, ranging from litres for planetary ball mill, mixer mill or vibration ball mill to several 100 litres for horizontal rolling ball mills.

Planetary ball mills are often used for such reactions. Figure 1 shows the operating principle of planetary ball mills, where rotation of grinding... Get Price. AHM Horizontal Agitated Media Mill hosokawaalpine ... (PDF) BICO Inc. The Bond Ball Mill is a small universal laboratory mill used in calculating the grindability of all ...

principle of ball mill pdf grinding: an overview of operation and design Minerals Research . energy relationships, types of mills, control factors and design of such circuits.

Operations And Maintenance For Ball Mill. ball mill principles and maintenance sife. ball mill principles and maintenance Pos tentang Ball Mill Operations and Maintenance yang Informasi jadwal training / Pelatihan indonesia 2017 operating principles and fundamentals) Mill operation maintenance of a ball mill pdf lvdivseacadets

ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS I. INTRODUCTION AND PRINCIPLES In this presentation we will discuss the principle of the Attritor and its applications. The Attritor is a grinding mill containing internally agitated media. It has been generically referred to as a "stirred ball mill."

The operating principle of the ball mill The operating principle of the ball mill consists of following steps. In a continuously operating ball mill, feed material fed through the central hole one of the caps into the drum and moves therealong, being exposed by grinding media.

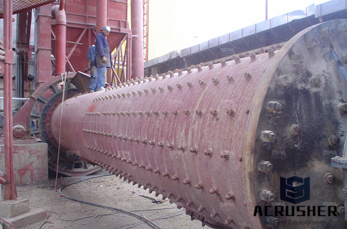

Ball mills are commonly used for crushing and grinding the materials into an extremely fine form. The ball mill contains a hollow cylindrical shell that rotates about its axis. This cylinder is filled with balls that are made of stainless steel or rubber to the material contained in it.

Torrey Hills planetary ball mills have been utilized to make many kinds of alloy powders, such as nano crystalline hard alloy, Nd 60 Fe 20 Al 10 CO 10 noncrystalline alloy powder, and Al 2O3/Al compound powder. 2. Operational Principles planetary ball mill consists of a revolving sun wheel and four rotating milling jars.

Hammer mill is the most widely used grinding mill and among the oldest. Hammer mills consist of a series of hammers (usually four or more) hinged on a central shaft and enclosed within a rigid metal case.

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell. A ball mill consists of a hollow cylindrical shell rotati

Welcome to STK. Founded in 1987, STK has attained 124 patents during the production of crushers mills over the past 30 years. 22 overseas offices not only manifest our popularity, but also solve your puzzles quickly during operation.

Application: Energy saving mining ball mill is a key equipment in beneficiation is widely used in ore dressing production line such as Gold ore, Cooper ore, Magnetite ore, Antimony, Calcite, Kaolin, Mica, Clay, Bentonite etc Ferrou metal or Nonferrous metal materials.

Planetary ball mills 9 . Vibration Mills 10 . Mixer Mill MM 400 11 Feed material: hard, mediumhard, soft, brittle, elastic, fibrous Material feed size: ≤ 8 mm Final fineness: ~ 5 µm ... Principles of green chemistry Ball milling – solvent free approach

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION CASE STUDY Batra*, D. Bhaskara Rao** and Raju Goyal*** ... Ball mills are predominantly used machines for grinding in the cement industry. Although ball mills ... The mill was operating at an average output of 135 t/h OPC and specific power consumption of

iron ore ball mill operation principle · The ball mill working principle is used to grind many kinds of mine and other materials, or to select the mine. ball mill working principle is widely used in building material, chemicalindustry, etc. Obviously, the longer the ball mill working principle .

Ball mill operation is often regarded as something of a mystery for several reasons. Ball milling is not an art it''s just physics. The first problem will ball mills is that we cannot see what is occurring in the mill. The other problem is that many of the independent variables .

Several types of ball mill exist. They differ to an extent in their operating principle. They also differ in their maximum capacity of the milling vessel, ranging from litres for planetary ball mill, mixer mill or vibration ball mill to several 100 litres for horizontal rolling ball mills.

Grinding in ball mills is an important technological process applied to reduce the ... depending on the type of the mill, the operating conditions and the type of the ... principle in the development of each model is to establish mass balance or energy

WhatsApp)

WhatsApp)