WhatsApp)

WhatsApp)

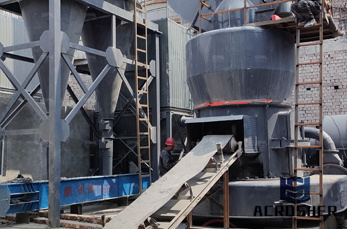

Dry process The dry processing of kaolin is relatively simple, has lower costs, lower yields and lower quality products than the wet process. The general flowsheet uti lized in dry process is shown in Fig. 6. The essential feature of the dry process is to dry the crude clay so that it can be pulverized.

May 05, 2016· Which is Best? I''m often asked this question by taxidermists: should I wet tan or dry tan my skins? In some instances, the answers are quite obvious and selfexplanatory. In other instances, they aren''t. For example, all flat hides [.]

What Are the Differences Between the Wet and Dry Processes of a Cement Manufacturer? The wet process of cement manufacturing involves adding water to finely crushed raw material, such as limestone, clay or iron ore, in a proportion of 35 to 50 percent water to 50 to 65 percent raw material to make a slurry that is fed into a cement kiln ...

SHOTCRETE: WET PROCESS VERSUS DRY PROCESS BY DENNIS BITTNER S hotcrete was invented in the early 1900s by American taxidermist Carl E. Akeley by propelling dry material through a hose with water injected at the nozzle to fill plaster models of animals. Soon after, it was discovered that the same method was an effective way to repair buildings. In

Flavor Characteristics Due to Coffee Processing. DryProcess: The dryprocess (also known as the natural method) produces coffee that is heavy in body, sweet, smooth, and dryprocess is often used in countries where rainfall is scarce and long periods of sunshine are available to dry .

Coffee processing removes the fruit from the seed; skin, pulp, parchment, and silverskin slough off to reveal a beautiful bean. Coffee is typically processing using one of two methods: washed process (also called wet process), or natural process (also called dry process).

Mar 28, 2018· Wet process Mixing of Raw materials in wash mill with 35 to 50% water. Materials exiting the mill are called "slurry" and have flowability characteristics. Size of the kiln needed for manufacturing of cement is bigger. Raw material can be mixed easily, so a better homogeneous material can be obtained Fuel consumption is high,.

Mar 06, 2018· Dry Cleaning vs. Wet Cleaning Despite what people may say, cleaning clothing and other textiles is a science. Professionals from all over the world have worked hard to determine the best cleaning methods for all types of fabrics — and that includes dry cleaning and wet cleaning.

Finally, clays for the preparation of ceramic slips would reasonably be expected to be ground wet, since the initial condition of the clay is wet and it is required in a wet form for subsequent processing. Clearly, in such a case, dry grinding, which would involve drying, would be uneconomic and would only be adopted in very special circumstances.

KaolinProcessing, Technology, Applications, Equipment, The production process features the separation of kaolin from quartz and feldspar by dry and wet processing KaoliniteWikipedia Rocks that are rich in kaolinite are known as kaolin / of kaolin are supplied and transported as dry energy barriers involved in the nucleation process.

Ask The Expert Wet Process VS Dry Process Shotcrete. Shotcrete was invented in the early 1900''s by American taxidermist Carl E. Akeley by propelling a dry material through a hose with water injected at the nozzle to fill plaster models of animals. Soon after, it was discovered the same method was an effective way to repair buildings.

Kaolin is an important industrial mineral having numerous uses and requiring various market specifications. High brightness kaolin clays represent a continuing challenge to the producer. An advancement in this field of Kaolinite Clay Beneficiation has been a patented process developed by Minerals and Chemicals Philipp Corporation and termed Ultra Flotation.

Nov 20, 2018· Kaolin ore processing mineral ...kaolin mining and processing equipment .Kaolinite processing equipment,kaolin processing plant for sale. ... Drytype and Wet .

process flow diagram of kaolin clay roomwitha, process flow diagram of kaolin clay KGSBull 191, pt 1Testing of Kansas Clays or Shales for Non, Aug 16, 2011, This treatment is particularly effective on the highkaolin clays from the Dakota, Flow chart for processing benneficiated clay or,, wet process flow chart for kaolin .

Imerys switch from traditional wet extraction methods to a dry mining process at two mines in their Western Area kaolin operations. Imerys, the world leaders in industrial minerals, have recently invested £ million to convert the operation of two of their largest china clay quarries in Cornwall from traditional highpressure wet extraction into classical extraction and processing of the ...

Find the Right and the Top Dry and wet process for kaolin ... Dry milling TiO2 Wet milling Burner ... SBM Mineral Processing Dept. Home Products Mineral ... >>TYY LXP. The Ethanol Production Process Wet Milling. Wet Milling Process The Ethanol Production Process ... The fermentation process for ethanol is very similar to the dry mill process.

Mar 27, 2018· Wet process 1. Mixing of Raw materials in wash mill with 35 to 50% water. 2. Materials exiting the mill are called "slurry" and have flowability characteristics. 3. Size of the kiln needed for manufacturing of cement is bigger. 4. Raw material ca...

Dec 09, 2011· The two primary methods are dry processing and wet processing; the names give us hints as to how each process occurs. Dry Processing Coffee Beans. Dry processing coffee beans is the older method of the two. This method is rather simple. It involves washing the coffee cherries and leaving them out on racks to dry in the sun for several weeks.

WHEN WATER IS NOT AN OPTION 5 Environmental drivers are the largest contribution to changes in food and ... Program for Dry Processing Environments Dry vs. Wet Sanitation Water Management Cleaning and Sanitizing Hygiene Pest Elimination Plant Traffic and Zoning Training Validation

May 04, 2012· Dry Processing. Two basically different processes are used to refine kaolins and remove the major impurities. The simplest process is called air flotation or the dry process. The properties of the finished product depend to a large extent on those properties inherent in the crude kaolin.

Dec 12, 2018· These are generally contrasted with "wetprocess" or "washed process" coffee. This dry process vs wet process distinction will really have an impact on how "fruity" vs "classic" the flavor profile of the coffee in your cup will be.

dry processing of kaolin versus wet processingCorn Milling Wet vs. Dry AMG Engineering Blog Corn wet milling and dry milling are the predo. Get Price. Chat Online. Kaolin EICL. The mined and sorted kaolin is then subject to processing by a wet route to produce processed kaolins with desired properties for various applications.

Mar 28, 2018· Wet process 1. Mixing of Raw materials in wash mill with 35 to 50% water. 2. Materials exiting the mill are called "slurry" and have flowability characteristics. 3. Size of the kiln needed for manufacturing of cement is bigger. 4. Raw material ca...

A process flow diagram for kaolin mining and dry processing is presented in Figure, and Figure illustrates the wet processing of kaolin. In the dry process, the raw material is crushed to the desired size, dried in rotary dryers, pulverized and airfloated to remove most of the coarse grit. Wet processing of kaolin begins with

WhatsApp)

WhatsApp)