WhatsApp)

WhatsApp)

We manufacture this critical heat resistant castings component for the cement plants . These heat resistant castings are used for working temperature upto 1100 degree celcius. Following are the various types of castings that are needed by the cement plant : Cooler Grate Plate Folax Colax Coolers ...

Castings combine stone concrete models by using Quikrete® Vinyl Cpmcrete Patcher, 1/2" wire hardware cloth, WD40 (#7051Stone Cement covers all the details) into textured casting master sheets – large 15" x 15" x .020 styrene plastic sheets (below). Cast entire buildings, roofs, foundations, portals, or whatever.

After the clinker is cooled, cement plants grind it and mix it with small amounts of gypsum and limestone. Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects.

from ready mix concrete plant in washout operations, may be used as mixing water if it is stored such as to prevent contamination by deleterious matters to concrete and the water drawn from the storage outlet. Acceptable quality is identified from past service records or tested to requirements given in Tables 3 and 4 in the standard.

These cement plant castings are principally used in the segment of cement manufacturing. All our inner segment castings conform to the ISO quality standards and can be customized as per the specific requirements of our esteemed clients. View Complete Details. Contact Seller Ask for best deal.

More than 250,000 people work in concrete manufacturing. Over 10 percent of those workers 28,000 experienced a jobrelated injury or illness and 42 died in just one year. Potential hazards for workers in concrete manufacturing: Hazard: Exposure to cement dust can irritate eyes, nose, throat and ...

We know that in periods of unplanned down time or critical situations, thousands—if not millions—of dollars can be lost each day. From the quarry to the kiln, Scot Forge delivers the metal components needed to keep your plant grinding. Forged wear parts for the Cement Industry. Quarry: crusher shafts, eccentrics, ring gears, bull gears

If you are looking for a Concrete Plants, check out our upcoming heavy equipment auctions to find used Concrete Plants for sale. Popular Types. Central Mix Plant (3) Concrete Batch Plant (10) Concrete Plant (6) Popular Makes. Besser (1) CAES (1) Custom Built (2) Ross (2) Stetter (2) Vince Hagan (2) Popular Products.

A kind of granular and powdered material made of adding a certain amount of binder by the refractory material. It has high fluidity and is suitable for forming refractory material. Compared with another unshaped refractory, the binder and moisture...

castings for pre heaters, kilns and coolers in cement manufacturing Cast not fabricated Some operators of pre heaters, kilns and coolers use fabricated tubes, but The Group Industries recommends cast dipping tubes, segmented along their height and circumference.

The construction joint shall be pre decided and fixed prior to start of the concreting. It is planned to have two construction joints for main building as decided. In case of major break down of the Batching plant, the additional Construction joint may be left. The location of the construction joint shall be at the onethird span. Construction joint shall be straight and have profile of ''L ...

May 29, 2010· These regulations affect 62 product categories used by the concrete industry, including many types of form release agents. It is important to be aware of the VOC''s content in all products used in the plant, including release agents, or to assure the materials used are VOC compliant.

Jan 22, 2017· THE SOUND IS REALLY LOW. Sorry! The basics of concrete, which is made up of cement, aggregates (sand or other materials), and water. Notice: When I say "cement.

We work with the end user to develop castings for wear parts used in the cement industry of all types, and can quickly generate prototypes, and production volumes. As a ISO 9001 certified company, strict QA and QC programs are in place at many levels to insure quality.

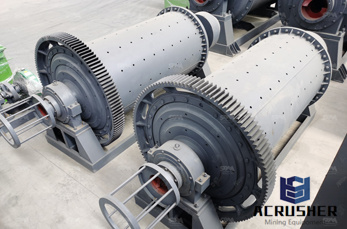

We understand the different requirements and equipment being used in the cement plants and can offer same as per your requirement. Similarly design of castings like wear plates, cooler plates, kiln parts, mill liners and preheater parts are different as per plant supplier.

Cement Production Separator cones for cement made of KALMETALL W100 6+4, 3,000 mm Ø Lining pipe parts used for cement grinding with KALCRET BNX, up to 3,200 mm Ø ABRESIST fused cast basalt is a timetested protective material for cement separators Precise fitting of KALOCER high alumina ceramics, 13 and 25 mm thick

ready mix plant. 2. Shrinkmixed concrete is mixed partially in a stationary mixer and completed in a truck mixer. 3. Truckmixed concrete is mixed completely in a truck mixer (Fig. 106). ASTM C 94 (AASHTO M 157) notes that when a truck mixer is used for complete mixing, 70 to 100 revolutions of the drum or blades at the rate of rotation ...

Cement and Concrete Basics. In its simplest form, concrete is a mixture of paste and aggregates. The paste, composed of portland cement and water, coats the surface of the fine and coarse aggregates. Through a chemical reaction called hydration, the paste hardens and gains strength to form the rocklike mass known as concrete.

Cement plant spares and equipment We supply all major castings and wear parts for cement plants as per, We understand the different requirements and equipment being used in the cement plants,...

WhatsApp)

WhatsApp)