WhatsApp)

WhatsApp)

Cement grinding mill investment cost. ground with gypsum to make cement powder A breakdown of the production cost of cement is: energy 31%, raw materials and consumables 28%, production, labor and maintenance costs 30% and depreciation 11% PRODUCTION COSTS 2007 % Energy 31 Production, labor and maintenance costs 30 RMCO 28 Depreciation 11 TOTAL ...

CMC is a leading supplier of media mills, grinding mills and basket mills, and an innovator of dispersion technology. In addition to custom and toll processing, the company provides inventory management, packaging, labeling, storage of finished products, and a wide range of other services.

How fine is fine enough? Most home grain mill users are mainly interested in making whole grain bread with excellent rise and texture, and every one of our grain mills will produce an ideal grind for bread flour from a wide variety of grains. If you''re interested in making pastries, you''ll want a mill that can grind to an ultrafine texture.

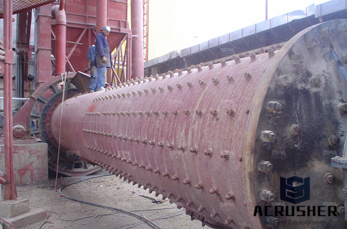

Outotec® MH Series Grinding Mills. Outotec® MH Series Grinding Mills offer a cost effective, and easy to operate and maintain grinding solution across the mill lifecycle. The MH Series includes a range of SAG, ball, and rod mills in standardized sizes with a capacity of up to MW installed power, and is based on over 100 years of ...

You are eligible for a full refund if no ShippingPasseligible orders have been cannot receive a refund if you have placed a ShippingPasseligible this case, the Customer Care team will remove your account from autorenewal to ensure you are not charged for an additional year and you can continue to use the subscription until the end of your subscription term.

WEDGE BUYING GUIDE. Fit your wedges to your swing type, style, course conditions. SM7 Wedges / Wedge Buying Guide. Consider your Loft, Bounce, and Grind Options. The Bounce and Grind options below display the loft, bounce, and grinds available in the Vokey Design SM7 wedges. Vokey wedges are labeled loft first, followed by bounce and grind. ...

m80s sweco vibroenergy grinding mill, s/s, 40 hp Used Model M80S Sweco VibroEnergy Wet Grinding Mill, 182 gallon maximum grinding capacity, stainless steel construction, jacketed chamber, with cover, on base with 40 motor drive, 3/60/440 volt, serial# 80M4681.

The discs of an attrition mill are generally in a vertical position so that materials not capable of reduction can pass by gravity out of the grinding area. Roller Mills. A combination of cutting, attrition, and crushing occurs in roller mills.

The grinding operation in a mineral processing facility typically consumes the majority of the energy used. In addition to energy, these mills consume special steel rods or balls as well as the steel mill linings. Combining all of these factors we see why grinding is one of the highest costs involved in mineral processing. Keeping these costs in

Maize flour milling machine/maize roller mill/wheat flour mill price Flour mill machine use the air flow recycle can remove the dust when processing m, a nd adopt the croloy roller which can make very fine flower with the good standard GB133586 (WHEAT FLOUR), very convenient, .

lower cost Autogenous and SemiAutogenous Mills The optimum solution for wet grinding. 2 AG/AG Mills AG/AG Mills 3 ''s AG/SAG mills accomplish the same size reduction work as 2 or 3 stages ... intermediate size ready for final grinding in a ball mill, pebble mill, or VERTIMILLTM.

copper ore grinding mill in india low costs high availability. wet grinding ball mill price Results 1 10 of 38 Cost Ball mills for wet grinding • To get the price of the ball mill . 90 million 23 million m3 37% . Get Price. Milling efficiency in distillery operations.

costs of grinding mill installations mineequipments. Installed cost comparison for cement grinding systems IEEE Xplore Past comparisons of total installation costs for a ball mill with high efficiency separator versus a VRM have indicated the higher equipment costs associated with .

MILLMAST, inmillerected liner suspension mill liner handlers available in maximum liner capacities up to 400kg; RME also has a liner handling solution for the growing number of installations of larger vertical grinding mills. The RUSSELL 3V vertical mill liner handler allows for the safe and efficient transfer of new and worn liners up to 10 ...

Crushers, Pulverizers, Grinders Knife Mill Blender Pulverisette 11 Knife Mill Blender Pulverisette 11 ... The Variable Speed Rotor Mill Pulverisette 14 Premium is a versatile, powerful mill for the fast grinding of mediumhard, brittle as well as fibrous materials and temperature sensitive samples. Quantity. Add to Quote request.

Metallurgical ContentBall Charge Motion inside a SAG MillSAG Mill OperationSemi Autogenous Design FactorsSAG Mill Operation ExampleProcess Plant DescriptionSAG Mill Design and Specification Operating Problems Since CommissioningDesign Changes and Future Operating Strategies AG and SAG mills are now the primary unit operation for the majority of large grinding circuits, and form the .

Grinding Mill Costs 10 M3 grinding mill costs 10 m3 minucharitabletrust. grinding mill costs 10 m3 Regrinding and fine grinding technology the facts and The latest development is a . grinding mill costs 10 m3 Grinding Mill China. price of grinding media in tons price of grinding media in tons. ball mill grinding ton/m3 .

ATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS I. INTRODUCTION AND PRINCIPLES In this presentation we will discuss the principle of the Attritor and its applications. The Attritor is a grinding mill containing internally agitated media. It has been generically referred to as a "stirred ball mill."

Buy used Ballmills from King Industries. We can help guide you to the best solution for your equipment needs. Used Mining Processing Equipment Grinding Mills, Crushers Process Plants

a hammer mill, producing maize flour of acceptable quality. These mills are in widespread use in rural parts of the world in areas where no electricity grid is available. Dieselpowered grain mills are limited to areas with access to fuel and spare parts. Plate 1 Traditional rubbing and hand grinding .

We have 44 years experience designing, manufacturing, installing and commissioning SAG and Ball Mill grinding equipment. We have nearly 30 years experience procuring and reapplying used grinding equipment to new mining projects, often with significant lead time and capital cost savings over the purchase of new equipment.

How fine is fine enough? Most home grain mill users are mainly interested in making whole grain bread with excellent rise and texture, and every one of our grain mills will produce an ideal grind for bread flour from a wide variety of grains. If you''re interested in making pastries, you''ll want a mill that can grind to an ultrafine texture.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Jan 06, 2014· "Mine operating costs and the potential impacts of energy and grinding" highlights that savings in milling costs will significantly affect total mine operating costs. The paper shows that energy costs typically comprise one of the largest ongoing costs of mining operations, of which 70% is devoted to the comminution of the ore.

WhatsApp)

WhatsApp)