WhatsApp)

WhatsApp)

Sep 02, 2016· Chrome Ore Beneficiation,Processing Plant,Chrome Grinding Machine Chrome ore beneficiation plant, chrome chrome ore beneficiation plant in china south african suppliers of chrome ore beneficiation ...

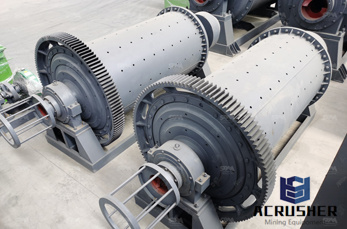

Ore Grinding Mills are used for the fine grinding as the last step in the reduction of an ore prior to concentration (gravity or flotation) or varies, depending upon the type of ore and the amount of reduction required. In addition, some of the older properties continue with methods that perhaps are not considered the best in light of recent improvements but that cannot be ...

Global Chrome ore Market Report 2019 Market Size, Share, Price, Trend and Forecast is a professional and indepth study on the current state of the global Chrome ore .

Maximising South Africa''s chrome ore endowment to create jobs and drive sustainable Under threat South Africa''s mature chrome value chain which provides over 200 000 jobs and contributes over R42 billion in GDP per annum

assumed the mined ore had been crushed in stage by a jaw crusher followed by secondary crushers to a product of maximum size of 3 to 15 mm in diameter. This crushed ore was then taken to rod or ball mills for grinding to the size required for flotation. From grinding mills, the pulp was fed to

crushing chrome ore size chrome ore grinding size analysis miningbmw. Limestone Quarry Plant In the limestone crushing plant, there are hammer crusher and impact crusher for big abridgement ratio, muslimbagh chrome grinding Chrome Ore Mining Plant Chrome crushing and Chrome, In Pakistan, Chromium ore is widely distributed in Muslimbagh, Wedh, Kharan, Dargai .

15 Costly Grinding and Polishing Troubles – How to Avoid Them Scratches, smearing, staining and deformation are just a few of the troubles you want to avoid when grinding and polishing for materialographic analysis. Don''t miss these important tips to avoid the 15 most common grinding and polishing troubles.

View of the abandoned Chrome Concentrating Company mill, opened in 1917, near the No. 5 chromite mine in Del Puerto Canyon, Stanislaus County, California (USGS photograph by Dan Mosier, 1972). Insets show (upper right) specimen of massive chromite ore from the Pillikin mine, El Dorado County,

Developed model uses ball size, ballore ratio, ball load and grinding time as the input variables and particle size distribution (<75 µm, <38 µm) as an output measurements. Data analysis. Experimental data were collected from lab to develop the mathematical model. A statistical analysis has been carried out to see

Tags: Chrome Ferro Chrome. Ferrochrome market morning review on 29 November, 2019. Fri, 29 Nov 2019 03:54:00 GMT : In Southwest China, the mainstream transaction price of highcarbon Ferrochrome is yuan/ton 50% basis, while it is yuan/ton 50% basis in Northwest, 6250...

RAPID ANALYSIS OF CHROMITE AND CHROME ORE 33 The procedures described here provide for the determination of Cr2O3, A12O3 . SiO2, Fe (total), FeO, MgO, Ti02, MnO, V2O3, NiO, CaO, and H2O. A flow diagram outlining the major steps in the analysis is shown in figure 5.

a complete procedure based on Image Analysis and Stereology is proposed for the ... test ore, it was possible to carry out the first experimental measurement of the ... indicating that the parameter is probably dependent on particle size. Finally, an industrial grinding circuit that process Taconite ore .

Chromite ore can be mined to produce chromite concentrate. It can also be crushed and processed. Chromite concentrate, when combined with a reductant such as coal or coke and a high temperature furnace can produce ferrochrome. Ferrochrome is a type of ferroalloy that is an alloy in between chromium and iron.

Recoverybysize kinetic analysis to determine where metallurgical improvements occur when converting to highchrome grinding media, in Proceedings 12th AusIMM Mill Operators'' Conference 2014, pp 217–224 (The Australasian Institute of Mining and Metallurgy: Melbourne).

Grinding Cost Analysis. According to the relevant data analysis, grinding equipment has an impact on grinding cost and performance, accounted for 30% in overall mineral operating costs, accounted for 50% in whole grinding cost, so the grinding equipment has a great influence on manufacturing operating rates, total grinding efficiency and total operation cost.

The VIBRADRUM® Grinding Mill has very few moving parts. A VIBRADRUM® Grinding Mill does not require the typical massive concrete foundation required of a conventional rotary grinding mill unit. Structural steel supports are designed as an integral part of the VIBRADRUM® Grinding Mill and simply bolted to a suitable loadbearing floor.

Keywords: mineral grinding, particle size analysis, process monitoring, extended product, process control, chromite concentration, gravity separation. 1. INTRODUCTION In order to enhance the performance of mineral processing equipment, a greater number of intelligent functionalities are being integrated into the equipment. The equipment ...

Without mineralogy, estimating the optimum Grind Size for Gold Ore Sample is most conveniently made by Laboratory Testing and the agitation leaching method, and it will be necessary to make up 3 or 4 bottle charges in order to have enough ore* for the subsequent screen analysis. Take an average sample of the ore and grind on the bucking table to pass No. 30 sieve.

Analysis and validation of a runofmine ore grinding mill circuit model for process control le Rouxa,, Craiga, ... A simple and novel nonlinear model of a runofmine ore grinding mill circuit, developed for process control and estimation purposes, is validated. ... product speci cation size and coarse ore is larger than the ...

Global High Chrome Steel Grinding Media Ball Market,, is a market research report by KD Market Insights that offers extensive and highly detailed current and future market trends in the global and regional/market. The report offers market size and structure of the overall industry based upon a unique combination of industry research, fieldwork, market sizing analysis, and .

procedure mineral processing grinding procedure mineral processing grinding Introduction to Mineral Processing Chevron Phillips Chemical. The process of froth flotation entails crushing and grinding the ore to a fine size. This fine grinding separates the .

Size distribution results based on sedimentation and elutriation, centrifuging, sieving, and electronic counting are meaningful only when the effects of sample collection and redispersion are negligible or clearly known. Microscopic analysis is regarded as the fundamental technique for counting and sizing particles.

Developed model uses ball size, ballore ratio, ball load and grinding time as the input variables and particle size distribution (<75 µm, <38 µm) as an output measurements. Data analysis. Experimental data were collected from lab to develop the mathematical model. A statistical analysis .

Dec 12, 2016· This video is unavailable. Watch Queue Queue. Watch Queue Queue

WhatsApp)

WhatsApp)