WhatsApp)

WhatsApp)

Cement is seldom used on its own, but rather to bind sand and gravel together. Cement mixed with fine aggregate produces mortar for masonry, or with sand and gravel, produces concrete. Cement is the most widely used material in existence and is only behind water as the planet''s mostconsumed resource.

Cement is so fine that 1 pound of cement contains 150 billion grains. The cement is now ready for transport to readymix concrete companies to be used in a variety of construction projects. Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

Jul 08, 2019· How to Make Concrete. Concrete is a building material that''s comprised of fine and coarse materials bound together with cement. If you need to do improvements on your home, you may want to make some concrete .

How to Make Lightweight Concrete Blocks | DoItYourself. How to Make Lightweight Concrete Blocks By:, Step 4 Add Sand The sand is the part of the mix that makes the concrete heavier If you want the ultimate lightweight mixture, then only use one fivegallon bucket of sand, Although the process for making concrete blocks is rather lengthy ...

Cement in Delhi Delhi Cement Price in. Okhla New Delhi Get Contact Get Best Price Seen JK Lakshmi Cement Manufacturing Process Alternative Cements ACMs Intro Facts and Uses Types of Cement How Cement are Made How Cement is Made Cement Manufacturing Process How to fill Chases Large Cracks in Cement

JK Lakshmi Cement is one of the pioneers of the cement industry and rated as one of the best cement companies in India, known for its highest quality standards in its cement plants and factories.

Presence of colouring impurities in cement.Use JK White Cement, ... 1 Part of Ordinary Portland Cement 3 Parts of sand Add water to make a mix of semidry consistency which should be moist enough for compacting. ... MANUFACTURING PROCESS After demoulding, tile should be kept in .

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites. More than 30 raw materials are known to be used in the manufacture of portland cement, and these

Mar 29, 2019· How to Mix Cement. Whenever a project calls for a hard, permanent binding material, most professional and independent builders use cement. Before using cement, you need to mix it with sand and stone. While this process can seem...

Dec 06, 2018· After manufacture, cement undergoes a "carbonation" process wherein concrete exposed to CO2 and humidity slowly bonds with the CO2, storing the carbon in mineral form. Because concrete is porous, CO2 slowly can diffuse into concrete, carbonating the cement to a depth of 60 millimeters or more over a number of years.

As the dynamics of the cement industry change, successful companies are creating value by focusing on their micromarkets. Here''s how they do it. The bestperforming cement companies succeed by blending structural moves, such as changes in asset footprints or supply chains, with effective ...

Dec 03, 2015· this is a pavers tiles making machine from j k tiles machinery, J K tiles machinery is the worlds most trusted and technical machine manufacturer centered in INDIA. we make machinery for cement ...

Sep 24, 2017· White Portland cement has essentially the same properties as gray cement, except for color. It is readily available throughout North America. The color of white cement is determined by its raw materials and the manufacturing process. Metal oxides,...

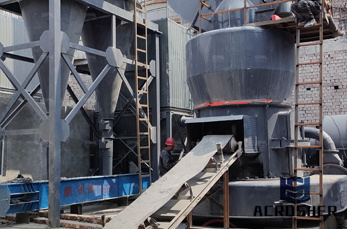

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the '' Clinker '' pages.

Cement concrete is a mixture of cement, sand and stone chips in correct proportions. The items are mixed in water and churned thoroughly in a concrete mixture. The process involves proportioning, Mixing, Compacting, Curing Drying. A concrete mix of 1:2:4 :: cement: sand: stone chips by volume are used for making paving blocks.

Jul 08, 2019· How to Make Concrete. Concrete is a building material that''s comprised of fine and coarse materials bound together with cement. If you need to do improvements on your home, you may want to make some concrete yourself. To create your own...

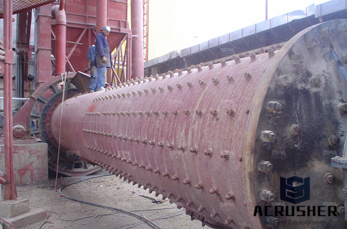

Jul 31, 2013· Charge is introduced into a rotary rotary kiln consists of a steel cylinder about 150meters long and 4meter diameter and rotates 30 to 60 turns per one end of .

Cement Manufacturing Process JK Lakshmi Cement, a member of the prestigious Organisation, is a blue chip company with an annual turnover of over Rs. 2300 crores (Rs. 23 billion). Launched in 1982, JK Lakshmi Cement (Sirohi Plant), an ISO 9001:2008 14001:2004 company, is built over an area of about 8 square kilometers, amongst the lush ...

Aug 30, 2012· The remaining cement is shipped in bulk quantities by mean of trucks, rails or ships. Cement Manufacturing Process Flow Chart. After explaining the complete process of cement making, flow chart would be like that. flow chart present the summary of whole process as shown below.

The J. K. Organisation is an Indian industrial conglomerate, with headquarters in Delhi, Kanpur and Mumbai. It is run by the Singhania family, which rose to prominence in Kanpur, India, under Lala Kamlapat Singhania.

When making concrete it''s important to use the correct concrete mixing ratios to produce a strong, durable concrete mix. To make concrete there are four basic materials you need: portland cement, sand, aggregate (stone), and water.

The watercement ratio is the weight of the mixing water divided by the weight of the cement. Highquality concrete is produced by lowering the watercement ratio as much as possible without sacing the workability of fresh concrete, allowing it to be properly placed, consolidated, and cured.

Manufacturing Process White Cement. At JK White Cement Works, Gotan we use technical expertise from Co. from Denmark and state of the art technology with continuous online quality control by micro processors and Xrays to ensure that only the purest White Cement is produced. We manufacture White Portland Cement through these 5 ...

process at JK super cement Nagpur, Maharashtra, India Construction. JK super cement. 1 connection. View anirudh wandhare''s full profile. It''s free! Your colleagues, classmates, and 500 million other professionals are on LinkedIn. Join LinkedIn Experience. process JK super cement.

WhatsApp)

WhatsApp)