WhatsApp)

WhatsApp)

Specializing in the sale of second hand cement plant equipment, and complete used cement plants. In addition to used and new surplus Cement Plant Equipment (rotary kilns, ball mills, vertical roller mills), NMI deals in many other types of machinery, including used equipment for Bulk Material Handling, Crushing, Grinding, Industrial Mineral Processing, and Power Plants

Leading manufacturer of Chinese cement machinery; large mining mill production and export company; China rotary kiln production champion Group,global export base of kiln and energysaving grinding mill equipment, is a model enterprise of

For raw grinding with relatively dry raw materials, the combination of the roller press and V separator is a viable alternative with far lower mill fan power. Cement grinding. For cement grinding, the technology development away from ball mills has taken a different route.

cement plants – from the crusher to the dispatch, from the field level and production ... In the Industry Suite Cement, the worlds of automation and power engineering merge into one comprehensive and modular offer for your needs – including the required services ... to adjust the grinding plant so that energy losses are kept as low as possible.

It can save 30 of power per ton compared with traditional ball mill. At the same time it has many advantages such as less auxiliary equipment multiple functions small occupied area and little dust pollution. It is widely used in clinker grinding production of cement plant and grinding plant.

CEMENT PLANT LENGFURT AND GRINDING PLANT MAINZ, GERMANY Cement plant Mainz. Cement mill in Lengfurt. SIKA SOLUTION Grinding Aids reduce the attraction of fine particles and lower agglomeration and mill coating. They increase the productivity (t/h) at constant power (W) which results in considerable energy savings.

The energy audit and conservation project was carried out in the cement plant to assess the performance of its various subsections and utilities such as pyroprocesses, fans, compressors for Cement Manufacturing. This project work also strives to .

May 27, 2019· This video is unavailable. Watch Queue Queue. Watch Queue Queue

Slag powder is highperforming admixture for concrete in that it increases the concrete''s ability to resist compression, tension, shear, and bending stresses. A major trend that characterizes the building material industry is to replace equal amount of cement with slag powder in making concrete or cement products.

Cement manufacturing as a process and as a core industry has undergone many stages of transformation in recent years. CPG holds deep domain knowledge of the industry and hence, is equipped to offer customized service that are directed to meet the needs of clients from cement plants.

Kampala Cement Co Ltd is a new Cement Manufacturer in Uganda. The plant has installed capacity of one million tons of cement under brand names of Nyati .

Star Cement operates one /yr integrated cement plant in Ras alKhaimah, one /yr cement grinding plant in Abu Dhabi and one 900,000t/yr cement grinding plant in Ajman. Star Cement owns the largest number of cement plants in the UAE. Sharjah Cement operates a 2Mt/yr capacity cement plant in Sharjah. The plant was commissioned in 1977 ...

China Cement Grinding Plant manufacturers Select 2019 high quality Cement Grinding Plant products in best price from certified Chinese Mining Machine manufacturers, Grinding Machine suppliers, wholesalers and factory on

Modern machinery is being sourced from renowned cement machinery manufacturer M/s Thyssen Krupp. The plant will source its raw material from both internal and external sources such as fly ash from NTPC power plant and clinker for grinding from Nimbahera and Mangrol.

HOLTEC has undertaken Performance Optimisation of the cement grinding circuits by doing process diagnostic studies in many cement plants. The paper describes the approach for the process diagnostic study for the optimisation of a ball mill circuit and is supported with typical case study done by HOLTEC in a mio t/a cement plant.

Apr 11, 2016· The Dangote Cement Plc has commenced the construction of a new cement grinding plant in Cote d''Ivoire. The cement plant will produce 3 million metric tonnes of cement per annum. The cement plant is being erected on over 60 hectares of land, next to the New Industrial Park in Yongbon, a city just outside Abidjan, the nation''s capital.

VSK CEMENT / CLINKER GRINDING PLANTS QUESTIONS / ANSWERS POWER CORRECTION SYSTEMS INC. 1800 S. ROBERTSON SUITE #419 LOS ANGELES, CALIFORNIA USA PAGE 3 ANSWER: We have supplied turnkey projects directly to a number of customers. However, we has not tied up with any large construction group on an exclusive basis.

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement plant.

Aug 25, 2011· On average, MPC systems allow cement plants to reduce their energy consumption by 3% to 5%, as well as provide better product quality and capacity improvements. Energy management profit . Armed with optimized production information, manufacturers can then project, in advance, how much energy will be required for similar loads or batches.

Cement plant locations and information on United States can be found below. For full access to the database, purchase The Global Cement Report™, 12th Edition ...

Energy Efficiency Improvement and Cost Saving Opportunities for Cement Making An ENERGY STAR® Guide for Energy and Plant Managers August 2013 ENERGY STAR is a Environmental Protection Agency Program helping organizations and individuals fight climate change through superior energy efficiency. Document Number 430R13009

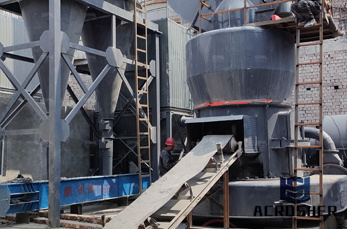

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc. Application : Cement Plant, Clinker Grinding Unit, Thermal Power Plant Capacity : 50250 t/h

At present, it has completed over 60 new dryprocess cement clinker production lines of various sizes ( tons / day), more than 10 pure low temperature waste heat power generation projects for cement clinker production lines and over 20 cement grinding station projects. We are a professional Cement plant design consultant.

India: Dalmia Bharat Cement will invest US492m in projects to expand its cement production capacity by 8Mt/yr to 34Mt/yr from 26Mt/yr. The sum includes a consolidated investment of US422m in brownfield developments in Eastern India to increase integrated capacity at its Rajgangpur plant in Odisha by /yr, and at its Kasba plant in West Bengal by /yr, to /yr and /yr ...

WhatsApp)

WhatsApp)