WhatsApp)

WhatsApp)

ATOX ™ raw mill880 Кб. Working principle The ATOX raw mill uses pressure and shear generated between the rollers and the rotating table to crush and grind raw Optimised separation process Rotor seal Seperator top view Optimum mill performance depends on optimum separator .

Browsing for iron ore for sale? The best online shopping experience is guaranteed! 53,768 iron ore products from 17,922 iron ore suppliers on for sale are available!Talk with suppliers directly to customize your desired product and ask for the lowest price, good discount, and shipping fees.

and liquid wastes, but according to this review, palm oil mill effluent (POME) has been singled out by the operators as the most expensive and difficult waste to manage. This paper aims to present the potentials of POME as a resource that can contribute to world economic and sustainable development.

Apr 19, 2013· Cyclonic separation – Wikipedia, the free encyclopedia. A simple cyclone separator . An alternative cyclone design uses a secondary air flow within the cyclone to . Cyclones are also used in oil refineries to separate oils and gases, and in the cement industry as .

raw mill in malabar cements pkd. Our Purpose And Belief. LM Heavy Industry is committed to provide the global customers with the firstclass products and superior service, striving to maximize and optimize the interests and values of the customers, and build bright future with high quality. All;

Product Description : Vilnesh Vibro Screen is one of the most versatile Machine, which can perform the operations like classification, grading, oversize or undersize removals, dedusting, dewatering, fiber recovery, filtration or any type of size based speration. 600, .

"Magnetic Separator For Rice Mill" Get ready to know about the latest magnetic separator for rice mill, which is known for the best separation process.. Importance of magnetic separators . From last many years, industries are using magnetic separators for a wide variety of applications.

The almond kernel separator machine is an essential machine for the use of almond and walnut cracked machine . When the almonds are pulverized, the raw materials mixed with the crushed shell and the kernel are placed in a machine to separate the apricot shell from the almonds.

screening. When the oats enter the mill, they pass under a magnetic separator to remove foreign metal objects, a very common practice in many foodprocessing operations(7). The oats then experience a series of rotating or oscillating screens that can both retain large objects (such as straw, sticks and stone) and let small objects such as ...

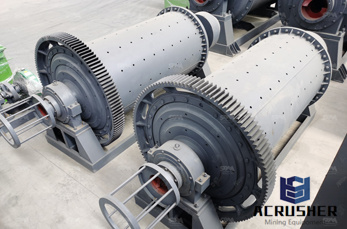

ore equipment wet ball mill. Wet Ball Mill For Copper Ore Processing Plant China, Accoridng to whether it need to . which shows that in both capacity and efficiency grinding was at its best with small . Equipment Manufacturer JXSC JXSC Mining Equipment for sale! . gold wash plant, magnetic separator, magnetic separators, flotation machine, etc.

Raw Mill In Cement Plant,Cement Making Plant. It''s a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, ore dressing of ferrous metal and nonferrous metal, etc.

specific beneficiation and metallurgical treatment to get the best product at lesser cost. ... wet high intensity magnetic separator, rod mill and ball mill. ... The JSPL, SAIL and EMIL are in process of installing the low grade iron ore beneficiation plant in this region. All these plant will be based on haematite ore as raw material. ...

dominant raw material for starch manufacture. Most of the development took place in the, which is the largest producer of maize worldwide. The manufacture of starch from maize by wet milling is schematically in dicated in Figure 2. The figure also indicates the produc tion of nutritive sweeteners and dextrin as many wet mill

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the ...

mill (CM) is fed with raw materials. The milled product is fed via a recycle elevator to a dynamic separator. The high fineness stream of the separator constitutes the final circuit product, while the coarse material returns back to the CM to be ground again. A .

AVAILABLE AND EMERGING TECHNOLOGIES FOR REDUCING GREENHOUSE GAS EMISSIONS FROM THE PORTLAND CEMENT INDUSTRY . Available and Emerging Technologies for Reducing Greenhouse Gas Emissions from the Portland Cement Industry Prepared by the ... to storage and then to the finish mill is similar to that used to transport raw materials ( belt

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw .

raw mill separator bearings 3rd generation. Our Purpose And Belief. LM Heavy Industry is committed to provide the global customers with the firstclass products and superior service, striving to maximize and optimize the interests and values of the customers, and build bright future with high quality. All;

Start studying Power Engineering 4th Class Ch 143. Learn vocabulary, terms, and more with flashcards, games, and other study tools.

These have been used for many years for the less exacting rawmilling process, but recently roller mills, in combination with highefficiency separators, have been used for cement grinding. The grinding action employs much greater stress on the material than in a ball mill, and is therefore more efficient.

Product Description : Vilnesh Vibro Screen is one of the most versatile Machine, which can perform the operations like classification, grading, oversize or undersize removals, dedusting, dewatering, fiber recovery, filtration or any type of size based speration. 600, .

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION CASE STUDY Batra*, D. Bhaskara Rao** and Raju Goyal*** Holtec Consulting Private Ltd., New Delhi ABSTRACT Grinding technology has been continuously improving with numerous innovations with a view to improve productivity and reduce power consumption.

• Cement raw material • Clinker / granulated slag • Industrial minerals, and • Ores The core elements of these plants are the Loesche vertical mills for drygrinding the abovementioned grinding stock. Loesche has developed and built the largest and most efficient grinding plants for its customers. Loesche plants

Spiral Chute Separator Customized Spiral Chute Separator. is a manufacturer and supplier of an extensive range of spiral chutes which are made with the best grade raw materials and are procured from trusted and certified vendors in the market.

WhatsApp)

WhatsApp)