WhatsApp)

WhatsApp)

Lime Slaking Mill Spares. CONTACT US: sales Through it''s purchase on Clyde Carruthers in 1998 and the subsequent purchase of the assetts of Motive Traction, Clyde supply a complete range of spare parts for Lime Slaking Mills supplied by Clyde Carruthers or ClydeJaques. Rubber Mill Linings, Fasteners, Guide Rollers, Shaft Rebuilds, Wheels are but a part of the equipment .

Lime Slaking Mill. Lime Slaking Mill 911 Metallurgist A horizontal ball mill can be used as in a lime slaking circuit just as well as a vertimill test directly to the ore on the belt moving toward further crushing or grinding If high quality limestone and fuel are readily available near the mill site the . Get Price AN OVERVIEW OF LIME SLAKING ...

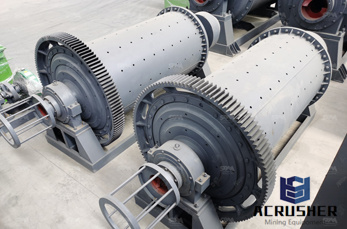

C. BALL MILL SLAKERS Ball mill slakers are an adaptation of ball mills, which originally were designed for wet and dry grinding, to lime slaking. Two types of ball mills are used for slaking, horizontal and vertical. Ball mill slakers are generally used where: the capacity required is too large for other types of slakers.

Ball mill lime slaking mill lime slaking mill slakers are 3 shows an attritor type vertical ball mill lime lime slaking mill liner what vertical mill for slaked lime slurry the dorroliver lime slaker is a reliable selfcontained lime slaking and grit it.

BALL MILLTYPE Westpro''s Ball MillType lime slaking design provides excellent slaking of lime while discharging no grit. Our system ensures the finest particle size by recycling coarse particles for further grinding. ADVANTAGES Safe, simple, and trouble free operation No practical upper limit for capacity Recycles coarse particles to the mill for

mill. The mixture is agitated and ground by the action of the mill producing hydrated lime slurry. The vertical ball mill slakers are the most common type of mill used for lime slaking. The water to lime ratio for the ball mill slakers is 4 to 5 parts water to 1 part lime by weight. This is the same water to lime ratio as used in the slurry

mounted ball mills suitable for quicklime slaking and regrind applications. The mills range from 600mm diameter for laboratory batch testing applications through to the largest mill currently available of diameter with an effective grinding length of SEW Eurodrive geared reducers are used exclusively on Lime Systems mills and all ...

The Lime Plant was designed by Portec and provides 6,000 TPH. The plant is comprised of the following items. Estimated new in 1996: 6'' diameter by 8'' Pug Mill Mixer, (2) 50'' Screw Conveyors, 4'' diameter Sweco Screen, (2) 3x3 Slurry Pumps, 4'' diameter x 4'' tall mix tank with lightning mixer, Prather valve for feed from bins, 3x3 Gallager Sump Pum, One set of switchgear and ...

Standard Horizontal Ball Mills are sometimes used for lime slaking. Considering that Ball Mills are designed for grinding, and the slaking process is simply a chemical process, it is obvious that the use of a Ball Mill for slaking is not the best choice of equipment in most cases. However, there are a few cases where the use of a Ball Mill ...

Ball mill slaker STT Enviro Corp. Horizontal ball mill slakers are similar to grinding mills commonly used in the mineral processing industry modified to withstand the temperature of lime slaking.

A horizontal ball mill can be used as in a lime slaking circuit just as well as a vertimill. Some operations apply the raw quicklime directly to the ore on the belt moving toward further crushing or grinding. In this application, it is necessary only to have a suitable lime storage tank with a live bin bottom and a means for metering the lime from the tank to the ore. Such metering devices may ...

BALL MILLTYPE. Westpro''s Ball MillType lime slaking design provides excellent slaking of lime while discharging no grit. Our system ensures the finest particle size by recycling coarse particles for further grinding. ADVANTAGES. Safe, simple, and trouble free operation; No .

The companies core products include rock breakers, low profile feeders, lime silos, lime slaking plants, roller mounted ball mills, silos and feeders for cement backfill, flocculant preparation ...

The Vertimill® is an excellent lime slaker, producing finely ground, homogeneous, slowsettling, highly reactive slaked lime in a simple onestep operation. Features designs and manufactures Vertimill®, ball mills, and SRR mills for limestone grinding and lime slaking applications.

C. BALL MILL SLAKERS Ball mill slakers are an adaptation of ball mills, which originally were designed for wet and dry grinding, to the job of slaking. Two types of ball mills are used for slaking, horizontal and vertical. Ball mill slakers are generally used where: § Capacity required is too large for other types of slakers.

Nov 04, 2011· This is a Sepro Mineral Systems lime slaking ball mill in operation. This mill is used to turn quick lime (CaO) into calcium hydroxide slurry [Ca(OH)2] for pH regulation.

The actual lime slaking process is performed either in a detention slaker or in a ball mill type slaker. In either case the slaking process is automated, controlled by a PLC which monitors both lime and water feed rates, slaking temperature and lime:water ratio.

traditional mortar mill for slaking of lime in india. lime mortar 2 Thoroughly compressed or beaten 3 Action mobilizes the lime putty and spread over the surface of each grain 4 Storing lime mortar for long time under a layer of water Lime mortar Traditional mixing techniques

Limestone grinding mills are usually 40 to 50% filled with ball charge; somewhat less grinding media is required for lime slaking. Carbon Capture from CoalFired Power Generation The limestone grinding mill is a horizontal ball mill.

Quick lime is withdrawn from the lime silo via a screw feeder. Dry lime and proportional water are mixed in the premix chamber and fed to the CLS Attritor Lime Slaker. The slaked lime and grit discharges from the slaking mill into the separation tank.

VERTIMILL® Lime Slaker draws from more than 100 years of mill design and manufacturing expertise and three decades of successful VERTIMILL® applications. The VERTIMILL® is an energy efficient and cost saving alternative to tumbling mills and paste or detention type lime slakers.

Sepro Tire Drive Grinding Mills are a reliable solution for small and medium capacity grinding applications and are suitable for ball, rod and pebble charges.. Sepro Grinding Mills come complete with a Variable Frequency Drive (VFD) package which allows you to fine tune the operation of the grinding mill based on the charge and mining application. No auxiliary drive is required to perform ...

Our experience cover all forms of lime processing, including; calcium oxide or quicklime, calcium hydroxide or hydrated lime, and various limestones and calcium carbonates. Transmin quicklime slaking plants are available as complete turnkey systems, comprising roller mounted ball mill slakers, silos and filling lines, bag breakers, mix tanks ...

Vertical Ball Mills. When lime or water quality is poor and/or when lime consumption rates are high, STT designs slaking systems utilizing a vertical ball mill. The total grinding process of a vertical ball mill utilizes all residual reaction value, virtually eliminates grit disposal problems, and significantly improves lime usage efficiency.

WhatsApp)

WhatsApp)