WhatsApp)

WhatsApp)

Dec 27, 2011· You probably know that silver is a metal that''s mined and then somehow refined to form the pure coins and bars we trade as bullion, but would you like to know a little more about that process? We''ve found an excellent little YouTube excerpt by the Discovery Channel on the process of mining .

Gold is processed by cyanide milling, a chemical procedure that separates 95 to 98 percent of the gold from raw mined ore. It is then refined to the gold standard purity, according to Mineweb. Heap leaching is a less expensive method of gold extraction, but it is a longer process and it recovers less gold than the cyanide milling process.

Of all the methods of extracting gold processing it from its ore, I used a few to evaluate two principal flowsheets in this case study. The flowsheets utilized operations that involved flotation, cyanidation and gravity concentration. Tests that mirror each of these unit operations were utilized to evaluate the principal flowsheets. This page offers a comparative review of gold recovery ...

Ore processing is a 24 hour operation. Ore is stockpiled (1) at the processing plant, and the process begins by feeding the ore into a hopper with a loader. The ore is conveyed, and lime is added (2) to raise the pH of the ore.

Gold processing, preparation of the ore for use in various products. Native gold is the most common mineral of gold, accounting for about 80 percent of the metal in the Earth''s crust. It occasionally is found as nuggets as large as 12 millimetres ( inch) in .

Mar 08, 2017· March 7, 2017 After a decade of exploration and building a gold processing plant in northern Ethiopia, Ezana Mining has become Ethiopia''s second large scale gold mining company, according to Capital. Ezega Mining is one of the sister companies in the Endowment Fund For Rehabilitation of Tigray (EFFORT).

Jan 23, 2012· Step #6 – Mining samples and determining processing. Once mining gets underway, samples must be taken to determine the precise metallurgical qualities of the ore. This is done in order to determine the appropriate processing technique. Step #7 – Processing (onsite) Once ore is extracted, processing it into pure gold must be done.

Likewise, the mining equipment used today helps reduce waste and chemical exposure throughout the various phases of gold mining. The Basics of Gold Mining and Processing. Placer deposits, such as streambeds where people can pan for gold, are not the typical locations used by commercial gold mining companies. The process begins when geologists ...

steps of gold processing in ezana mining . steps of gold processing in ezana mining. The Mining Process Waihi Gold. A slurry of ground ore, water and a weak cyanide solution is fed into large steel leach tanks where the gold and silver are dissolved.

Placer mining is the technique by which gold that has accumulated in a placer deposit is extracted. Placer deposits are composed of relatively loose material that makes tunneling difficult, and so most means of extracting it involve the use of water or dredging.

Successful gold mining is generally done in two steps: First is sampling or prospecting, and then, production. While some goldbearing creeks and rivers tend to have gold values dispersed throughout their entire streambeds, there is generally not enough gold to make a smallscale mining .

The entire process of gold mining can be broken down roughly into four steps: prospecting, mining, extracting and refining. Early discoveries of gold relied on the blind luck of someone spotting a yellow glint in a stream or in a crack between rocks. But the search today is more systematic and precise. First, geologists know more about how gold ...

Ezana Mining Development PLC October,2014. contents 1. Introduction 2. Regional Metallogeny of Northern Ethiopia ... • Procurement of Gold processing plant(CIP) is on progress • Production plan is 840 tons ore/day()/day ... and develop small scale gold mining • With out owning a singe mine Its involvement in assisting the local ...

Yet mining the ore is just one stage in a long and complex gold mining process. Long before any gold can be extracted, significant exploration and development needs to take place, both to determine, as accurately as possible, the size of the deposit as well as how to extract and process the ore efficiently, safely and responsibly.

Mercury is used in gold mining because of its ability to bind to gold to form an alloy which helps separate the precious metal from rock, sand ... finetuned each step of the process from crushed ore to gold pellet. Their method is as follows: The first step after crushing the ore is .

Jun 22, 2018· In order to even begin work, mining rights must be acquired, access roads must be constructed to help workers navigate the site, and a power source must be established. Production. Once these elements are obtained, the physical mining process—or, the first step of production—begins. The mining process can be broken down into two categories:

The practice of gold minerals beneficiation is optimized by using the information obtained from applied mineralogy. In this way, at the moment of development and select a process for treatment a gold ore, try to identify the gold minerals is the first step. Obviously, the detection of .

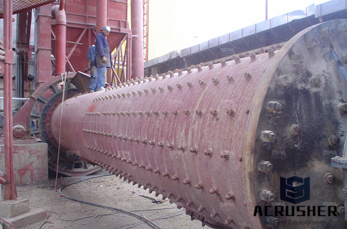

Removing the goldbearing rock from the ground is just the first step. To isolate pure gold, mining companies use a complex extraction process. The first step in this process is breaking down large chunks of rock into smaller pieces. At a mill, large machines known as crushers reduce the ore to ...

Aug 18, 2015· Mining operations are complex. They aren''t your runofthemill type projects. These billion dollar complexes consist of various interconnected projects, operating simultaneously to deliver refined commodities like gold, silver, coal and iron ore. It''s a five stage process and we''ve broken it down using GIFs. Exploration

Aug 06, 2015· We had a customer send us some very high grade gold quartz ore which we recovered troy ounces from only 300 lbs! We ran the quartz through our 1/21 ton per hour complete turnkey processor ...

The two gold refining methods most commonly employed to derive pure gold are: the Miller process and the Wohlwill process. The Miller process uses gaseous chlorine to extract impurities when gold is at melting point; impurities separate into a layer on the surface of the molten purified gold.

step by step gold mining process Coal processing system . Find the Right and the Top step by step gold mining process for your coal handling plant SBM, a mining machines manufacturer in china focus on your local solutions . Get Price. Goldma Gold Production Process Step by Step Explained .

Hello, we provide concise yet detailed articles on "Gold Choices: Process Of Mining Gold" topic. The information here is sourced well and enriched with great visual photo and video illustrations. When you find the article helpful, feel free to share it with your friends or colleagues.

The crude gold is melted and then treated with chloride. This converts any foreign elements or minerals still in the gold into chloride, which will then naturally drift off the gold. The result of this process is percent pure gold. The final step is to cast the gold into electrodes or anodes and place them in an electrolytic cell.

WhatsApp)

WhatsApp)