WhatsApp)

WhatsApp)

6,705 Mill Maintenance jobs available on Apply to Mill Operator, Operator, ... Of all rolling stock, performing preventative maintenance on the mill and. The employee is expected to. ... Discharge the ball mill safely and efficiently.

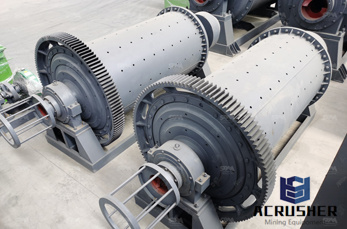

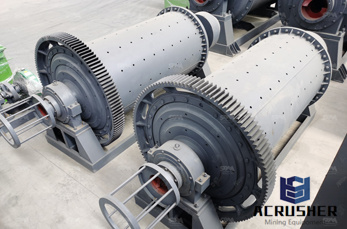

Ball mill preventive maintenance (PM) It is a frequency work to maintain and repair ball mills, AG mills and SAG mills. The maintenance work influences the rotational speed and service life of ball mills. In order to reduce downtime of ball mill, regular examination and .

Jan 20, 2011· Hello everyone, I have a problem with high levels of vibration at the supports of the pinion (fixed and floating bearings) of the cement ball mill. The kinemantic scheme with the measurement locations and several representative spectra and timewaves are in the attched file.

Putting a Ball or SAG Mill on Care and Maintenance. Previous Next ... and maintenance does not have to be complicated to the point where you need bridge erection equipment for lifting a Mill (AG/SAG/Rod/Ball). You actually need to lift a car higher than a mill. All you need to do is jack the mill .

Pouring the Media Back into the Ball Mill Jar Practice good housekeeping and maintenance with your mill. Clean up any spills immediately, and lubricate bearings as necessary. Tighten screws, nuts and bolts occasionally, and check the whole rig for wear and tear regularly.

As we all know, maintenance is very important for the equipment, mining ball mill as the key equipment which grind material, is suitablt for all kinds of ore and other materials. Because of the wide use of Ball Mill in mining indusry, in order to facilitate the better use of ball mill, Shanghai Clirik summed up ten tips for Mining Ball Mill Maintenance for your reference.

Apr 09, 2012· Ball grinder mill maintenance and repair is a regular work. The quality of maintenance and repair will affect the ball mill''s operation rate and life time. Here will introduce how to maintain and repair the Ball Mills. 1. Ball mill''s lubrication oil should be given out, clear out and change new oil after continuous running one ...

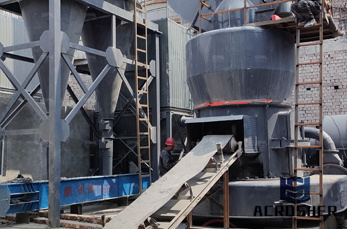

Ball Mill Maintenance Shop and Field work. Ball mill maintenance our shop and field crews make a unique combination to provide complete and up to date ball mill maintenance services. The shop is fully equipped with the large machining, fabrication, and engineering capabilities to rebuild your mill .

Ball mill is the largest consumption equipment of mining plant. The ball mill''s operating state directly influences the whole mill plant productivity. It''s also the biggest investment equipment of mill plant, and the wastage of the ball mill has a...

Methods to Maintenance and Repair the Ball Mill. The ball mill is a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc. Ball mill.

The ball mill uses the large iron balls in the cylinder to roll back and forth to complete the grinding process of the material. At present, the ball mill has been widely used in the cement, fertilizer, construction and other industries. In daily operation of the ball mill, proper maintenance of the equipment can effectively increase the service life of the ball mill, thereby saving business ...

Ball mills Ball mills are used for dry and wet grinding of different materials such as cement materials, cement, lime, and ceramic materials. PSP Engineering has continuously refi ned the design of its ball mills. Horizontal ball mills have become a reliable part of grinding plants Main characteristics of ball mills seated on shoetype bearings

Aug 20, 2014· With this in mind, the ball mill is an essential item of machinery, and its proper maintenance is an equally essential concern. You''ll already know that a ball mill gets its name from the manner in which it breaks down hard materials, like ores.

Dec 05, 2014· The operators should take certain precautions before they start operating a ball mill. Here''s a list of the most important safety maintenance steps that all operators should follow when using a ball mill: Planning – Planning ahead is a must. Operators should know exactly when to lock and stop the ball mill.

With more than 100 years of experience in ball mill technology, ''s ball mills are designed for long life and minimum maintenance. They grind ores and other materials typically to 35 mesh or finer in a variety of applications, both in open or closed circuits.

Ball Mill Maintenance Installation Procedure It is designed along sound engineering principles with quality workmanship and materials used in the construction of the ponent parts Your Ball Mill reflects years of advancement in grinding principles, materials, and manufacturing techniques

cement ball mill maintenance company in united . Introduction Ball Mill Liner Plates CompositionJianYe MachineryBall mill liner plates is an important spare part of ball mill and the service life will be different according to the raw Mill Maintenance and Installation Procedure 911 Metallurgist003, per foot of length of sole plate.

Jul 05, 2008· Outlines the various steps precautions and procedures that must be taken to safely and efficiently shut down a ball mill, enter, inspect, service (repair or perform routine maintenance), and ...

Ball Mill Preventive Maintenance. Iron or ball mill maintenance checklist deluxum ball mill preventive maintenance naipu miningug 11, 2015 ball mill preventive maintenance pm it is a frequency work to maintain and repair ball mills, ag mills and sag millshe maintenance work influences the rotational speed and service life of ball. Read More

Cement Ball Mills. A cement ball mill is designed to grind clinker, gypsum and for the drying of cement additives. It is a component in the cement making process. Today''s Ball Mills are typically designed with a slide shoe bearing. ... Maintenance Tips. If high bearing operating temperatures cause the mill to trip offline, consider increasing ...

Dec 26, 2012· Practical maintaining tips for correct running of ball mill. Share on Facebook Share on Twitter ... We should also maintenance the ball mill after the breakin period and do a good job in regular check. At the same time we should pay more attention to the oil exchange. 4. For the ball mill is a professional machine, the operator must receive ...

nqm 20 ball mill maintenance manual_Ball Mill Maintenance Installation ProcedureMetallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROU

Ball Mill maintenance work,Ball Mill machine wear . Ball Mill. Ball Mill is a kind of superfine grinding, its material grinding fineness is large,SBM Ball Mill is able to receive the superfine grinding market welcome ... Chat Online. Ball Mills PSP Eng.

Ball Mill Preventive Maintenance Checklist. Ball mill preventive maintenance august 11, 2015 030627 pm ball mill preventive maintenance pm it is a frequency work to maintain and repair ball mills, et price and support online kolkata maintenance check list of ball millaintenance check list ball mill preventive maintenance checklist preventive.

WhatsApp)

WhatsApp)