WhatsApp)

WhatsApp)

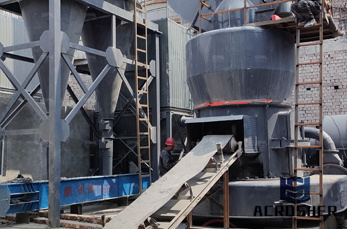

Mine equipment mainly includes Raymond mill, ball mill,roller mill, company,as a worldclass Raymond mill manufacturer, has a high reputation i Raymond mill,ball mill,vertical roll,grinding mill Grinding Equipment

The Application of Vertical Roller Grinding Equipment, Vertical Roller Mill Equipment: Vertical Roller Grinding Equipment, Vertical Roller Mill Equipment is the equipment specializing in producing fine and superfine powder of noninflammable, nonexplosive and brittle materials with Mohs''s hardness under six, such as calcite, chalk, limestone, dolomite, kaolin, bentonite, talc, mica ...

Oct 29, 2019· vertical roller mill flow chart india sukusrestaurant vertical roller mill flow chart india vaboda vertical roller mill flow chart india vertical roller mill is a type of grinder used to grind ...

1) Raymond mill works closely under the centrifugal force on the grinding ring rolling by shovel blade materials to roll grinding and grinding ring middle, material crushing grind into powder under the effects of stress, and then under the action of the fan to blow up into a powder material through analysis machine to achieve the required fineness of the material through the analyzer, who fail ...

Keywords: vertical roller mill, model predictive control, proportional integral and derivative control, artificial neural networks, fuzzy logic. 1. INTRODUCTION The VRM is a type of grinding mill integrated with multi functions such as grinding, drying and separation, used for grinding .

ROLLER PRESS. HIGH PRESSURE GRINDING ROLLS MAIN FEATURES First application 1984 Today worldwide more than 600 mills in operation. Throughput rates up to 1300 t/h. Grinding force from 2 to 20 Mega Newton. Efficiency to times higher than ball mill to times higher than vertical roller mill Cement finish grinding limited by PSD.

From pit to raw grinding, to preheater, kiln, and finish grinding, Columbia manufactures a full range of replacement parts for cement production. For example, we make large carbon steel mounting frames for roller mills; heat resistant steel preheater and kiln parts; and .

Atlas Vertical Roller Mill NETZSCH Grinding Disper. NETZSCH Ecutecs Atlas Vertical Roller Mills have been developed for more efficient fine grinding of soft to mediumhard materials The Atlas is a roller airswept mill designed for continuous operation with minimum maintenance The fundamental difference between the Atlas and other tableroller mills is the bearing arrangement for the grinding ...

Jul 31, 2012· The solution was applied first in the raw material millRM3, a vertical roller mill LM with a capacity of 505 t/h and a specific powerconsumption of the main drives (mill motor, mill fan and classifier) of 15,8 kWh/ mill is a vertical roller mill from Loesche."We are very satisfied with the Loesche LMmaster and the process experience ...

HC1700 Grinding Mill. HC1700 Grinding Mill is a newly developed largescale roller mill by Guilin Hongcheng. The equipment referenced the operating principle of pendulum mill and improved the swinging method. Without changing other parameter, the centrifugal grinding .

Raymond Bartlett Snow Milling Technologies Specialized for Efficient Grinding of Additives and Coal in Iron and Steel Plants ... vertical grinding surfaces (as shown in the picture) which is a suitable design forefficient ... The Vertical Roller Mill is an air swept mill with an integral classification system. Above

The advantages of the vertical roller mill include a high level of grinding efficiency combined with reduced energy consumption. For raw materials and cement clinker, the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation, ease of operation and maintenance, energy efficiency and product ...

Rolling bearings in the world''s largest vertical roller mill MVR 6700 C6: The largest vertical mill in the world, producing in Barroso, Brazil 000A86E4 Gebr. Pfeiffer is one of the technology leaders in the field of cement grinding and hard milling. Vertical roller mills are used to grind cement raw material, cement clinker, blast furnace ...

Replacing a Ball Mill with a Vertical Roller Mill, HighPressure Grinding Rolls, ... HighPressure Roller Press for Finish Grinding ... to reduce their operating costs and improve their carbon footprints. The reports provide a plethora of practical

Vertical roller mills (VRM) can replace ball mills or tube mills used for preparing coal. Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding. According to MIIT, grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal powder in a ball mill.

Permit Summary – Addition of a Kiln and Related Operations . At CEMEX Facility in Clinchfield, GA . ... Has the facility considered combining the raw material drying step with vertical roller mills by utilizing waste heat from the kilns or clinker coolers? ... Does the design of the finish grinding operation include roller presses or roller

Proven commercially, the OK™ mill is the premier roller mill for finish grinding of Portland cement, slag and blended cements. The mill consistently uses five to ten percent less power than other cement vertical roller mills, and in comparison with traditional ball mill operations, the energy requirements for the OK cement mill is

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION CASE STUDY ... • Roller press in semi finish and finish grinding mode • Vertical roller mill (VRM) ... A mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and ...

Calcium Carbonate Powder Vertical Roller Grinding Mill is suitable for huge capacity producing, widely used in grinding nonflammable and nonexplosive materials under (the Moh''s hardness), such as quartz, feldspar, calcite, talcum, barite, fluorite,

EPB1 Vertical roller mill Google Patents. The invention also includes a vertical roller mill for carrying out the new method the mill prising as is described for example in EPA0 017 342 at least one grinding roller which is urged by a double acting hydraulic cylinder against a grinding table rotating about a vertical axis. Live Chat

three units, has recently placed an order for a mill for cement grinding in its Teresa plant, the Philippines. The Horomill is also an attractive technology for the Asian cement market: four machines are operating in Vietnam and eight machines are installed in China, where six of them are dedicated to slag finish grinding.

The grindability result is the grams of fine particles, which pass a mm screen aperture size, produced per revolution of the mill. A standard procedure is used to determine this value. The lower WANG Jianhuai et al Grinding process within vertical roller mills: experiment and simulation 99 the value the harder the material is.

The single rotor primary impact crusher of the HPI series is used in the cement industry with grinding path, for the production of a raw material with an ideal grain size distribution for further grinding in vertical roller mills.

WhatsApp)

WhatsApp)