WhatsApp)

WhatsApp)

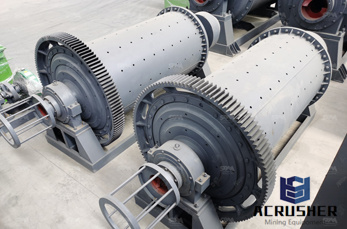

A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis. The balls which could be of different diameter occupy 30 – 50 % of the mill volume and its size depends on the feed and mill size.

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ).The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

During the last decade numerous protocols have been published using the method of ball milling for synthesis all over the field of organic chemistry. However, compared to other methods leaving their marks on the road to sustainable synthesis ( microwave, ultrasound, ionic liquids) chemistry in ball mills is rather underrepresented in the knowledge of organic chemists.

Hope Ball Ladies Golf Tournament Greenery Sale 113 Mills Avenue Greenville, SC 29605 ...

Ball Mills or Rod Mills in a complete range of sizes up to 10′ diameter x 20′ long, offer features of operation and convertibility to meet your exact needs. They may be used for pulverizing and either wet or dry grinding systems. Mills are available in both lightduty and heavyduty construction to meet your specific requirements.

For ball milling it is necessary that the milling media is made of a material harder than the sample. But in the case of boron carbide it seems difficult to find a harder milling media.

Wet or dry grinding by ball, pebble, or rod mill, to obtain the information on the various methods of grinding and the advantages or disadvantages of each. Two 12″x 5″ Laboratory Ball Mills, two pebble grinding jars on rolls, and one laboratory rod mill are available.

Mar 05, 2020· The new SAG screen and ball mill oilfield transformers installed in Q3 are performing as planned. We have increased the ball mill speeds and are operating at the targeted higher mill .

Oleg D. Neikov, in Handbook of NonFerrous Metal Powders, 2009. Tumbling Ball Mills. Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale.. Grinding elements in ball mills travel at different velocities. Therefore, collision force, direction and kinetic energy between two or more elements vary ...

The National Bocce Ball Association—the league''s governing body—works in collaboration with oncampus organizers, Student Activity Boards, Greek Service Organizations, and Intramural Departments—to maximize participation and fun for each participant. The College Bocce League is not sanctioned by the NCCA—Yet.

The mill was rotated horizontally at constant milling speed of 400 rpm at four levels of energy (––– kJ/g of sample) obtaining the amaranth flours. The ball milling was changed in rotational direction every 30 s. Milling energy values were selected as a .

Everything you need to learn to mill your own pyrotechnic compositions.

Nov 24, 2010· A ball mill is also commonly employed for fine grinding. In a ball mill, grinding energy is transferred to materials through media such as balls, rods, pebbles, by moving the mill body . For both types of mills the mechanisms by which particle size is reduced follow the same principles.

Ball Mills Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800''s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

Ball Mills Mineral Processing Metallurgy. In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals.

Ball Mill For Cement, Ball Mill For Cement Suppliers . Alibaba offers 13,950 ball mill for cement products. About 43% of these are mine mill, 5% are cement making machinery, and 1% are grinding equipment. A wide variety of ball mill for cement options are available to you, such as ball mill, raymond mill.

Building A Ball Mill Association Of Backyard Metalcasters. Mineral Processing Equipment: building a ball mill association of backyard metalcasters A type of mining equipment that can trigger the development and change of the beneficiation technology main core machines are ball mills, rod mills, flotation machines, magnetic separators, etc.

Ball is the largest manufacture of aluminum beverage cans in Brazil. According to ABAL, the Brazilian Aluminum Association, and ABRALATAS, the Brazilian Association of Can Manufacturers, the 2015 Brazilian beverage can recycling rate was percent. That means Brazil recycled around 292,500 metric tons of aluminum beverage cans.

West Point Association of Graduates, Bldg 698 Mills Road, West Point, NY 10996,, 800 BE A GRAD, redsash Open MonFri 8:00 5:00 EST. West Point Association of Graduates (WPAOG) is the Alumni Association for USMA

Unused Paul O Abbe One Piece Ceramic Ball Mill, Model OPCM67. 250 liter. Unused Paul O Abbe One Piece Ceramic Ball Mill, Model OPCM67. 250 liter, 19% alumina content. Approximate " diameter x " long. " inlet/outlet, 39" discharge height from the top of the base plate to hatch.

Ball mill association of indonesia members list company list suppliers distributors importers the ball mill is a key equipment to grind the crushed materials and the ball mill is widely used in powder making production line including cement silicate new type building material.

ball mills association printflyerscoza. A ball mill can grind and homogenize small sample volumes down to the nano range The Emax is an entirely new type of ball mill for high energy input the construction of ball mill fotoepilacijaeu Building a Ball Mill Association of Backyard Metalcasters Building a Ball Mill get price

Chapter 1, ''CarbonHeteroatom Bond Forming Reactions and Heterocycle Synthesis under Ball Milling'' by Brindaban C. Ranu, Tanmay Chatterjee and Nirmalya Mukherjee (Indian Association for the Cultivation of Science, India) covers carbon–heteroatom (C–N, C–O, C–S, C–Cl, C–Br) bond formation and synthesis of heterocycles under ball milling.

Wet ball milling was used to exfoliate graphite platelets into graphenes in a liquid medium. Multilayered graphite nanosheets with a thickness of 30 to 80 nm were dispersed into N,Ndimethylformamide (DMF) and exfoliated by shearforcedominated ball milling carried out in a planetary mill. After highspeed centrifugation, irregular shaped single and fewlayer graphene sheets (≤3 layers ...

WhatsApp)

WhatsApp)